Cold Saw Blades for Sale

Same-Day Rush Shipping Available!

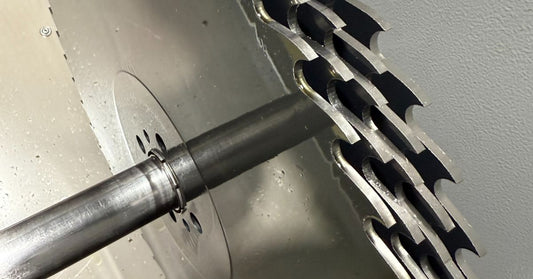

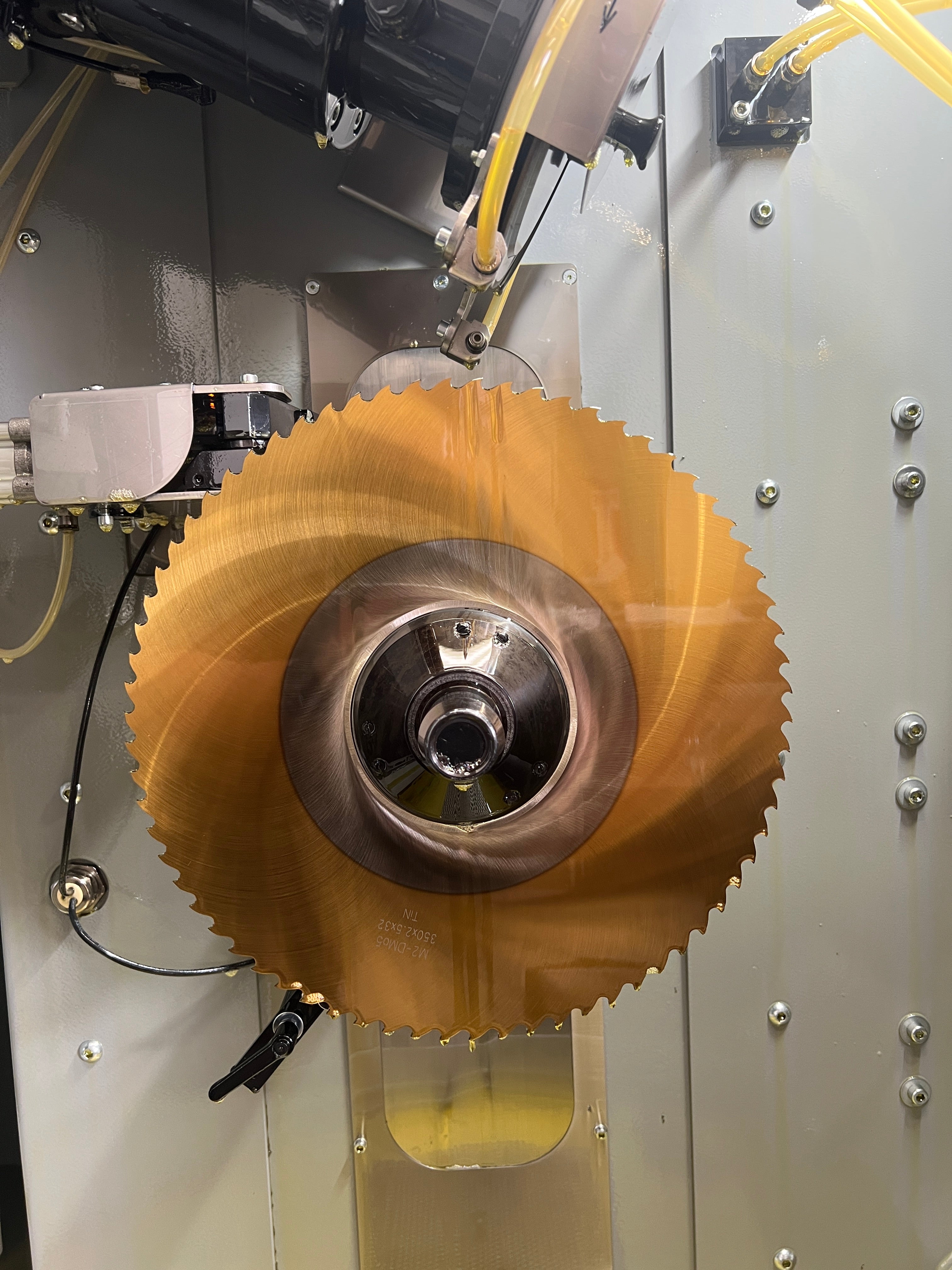

We are a proud USA based company! Cold Saw Shop offers the best value in cold saw blades for sale. We manufacture and stock HSS M2 & M35 (Co5 with cobalt) cold saw blades for every machine and application! We also have carbide tipped blades for dry cut machines and non-ferrous carbide blades for aluminum and non-ferrous applications.

If you are having issues with your cold saw blades life or performance, we would be happy to assist in troubleshooting with you and offering the best solution.

Call or email us directly anytime with any questions, concerns, or to get technical recommendations about our cold saw blades for sale: (855) 729-7732 | info@coldsawshop.com

Check out our tooth count calculator to assist you with determining the the optimal tooth count for your specific application.

The Best Blades Available

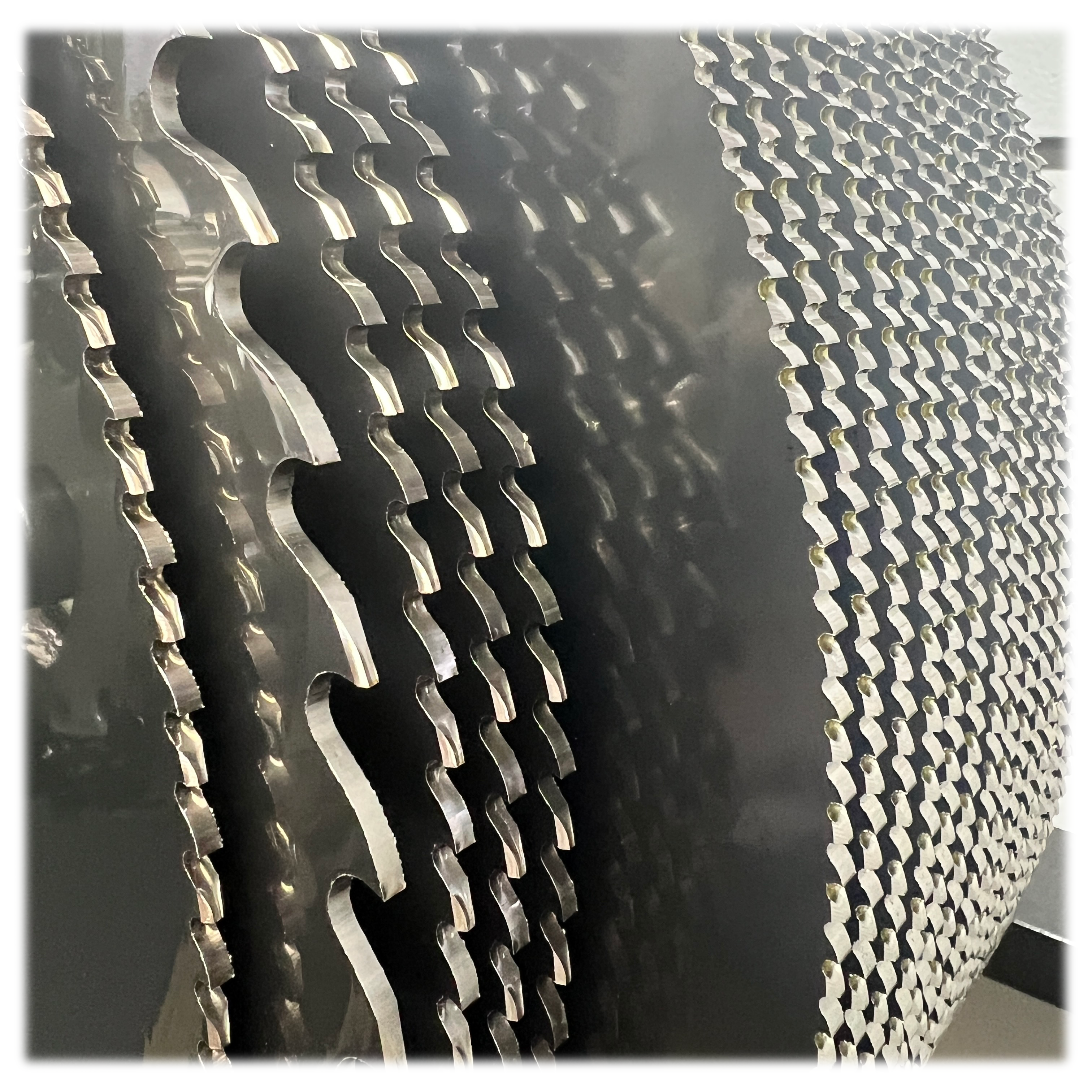

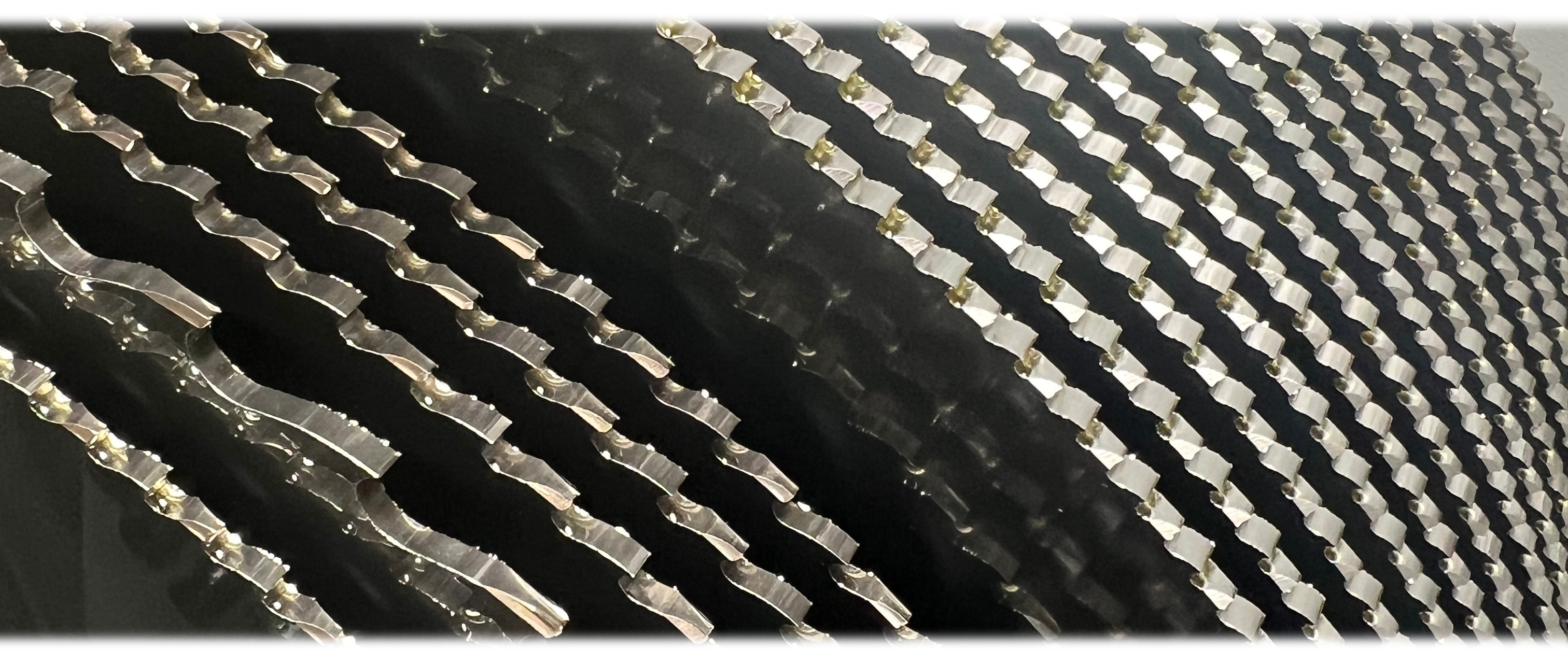

Our customers return because we use top-quality German-made machinery to manufacture cold saw blades with the best available steel.

While there may be cheaper options for steel and machinery, we refuse to compromise our standards for the sake of saving a few dollars. Our focus is on producing high-quality cold saw blades that you can rely on for uninterrupted performance. Shop for quality tools to complete all your metal cutting projects with ease.

Cold Saw Shop has decades of experience, and we strive to ensure our customers get the best quality product in ample time. We understand the importance of repeat business and we aim to earn your trust and loyalty. Shop our collection and place your order for cold cut saw blades today!

Here are a few recent testimonials:

“The blades we bought from you performed and lasted longer than the OEM blades from Doringer.”

Chris @ Flywheel Industrial Arts of VT

“The blades you sold us are the best we have ever used. That is why I take the time and spend the money to send them back to you for sharpening. Each time you sharpen them, they perform and last like a new blade.”

-Mike Smith Jr @ M.R.S. and Son LLC of PA

Collections

-

250mm Cold Saw Blades

Cold Saw Shop stocks a wide selection of 250mm cold saw blades...

-

275mm Cold Saw Blades

Find the cold saw blades you need at the Cold Saw Shop...

-

300mm Cold Saw Blade

At Cold Saw Shop, we understand the importance of using top-grade tools...

-

315mm Cold Saw Blade

The Cold Saw Shop carries many 315mm cold saw blades for the...

-

350mm Cold Saw Blades

The Cold Saw Shop sells quality 350mm cold saw blades at great...

-

Cold Saw Blades for Baileigh Cold Saw Machines

We make and sell blades to fit all cold saw machines. On...

-

Cold Saw Blades for Dake Cold Saw Machines

We make and sell blades to fit all cold saw machines. On...

-

Cold Saw Blades for Doringer Cold Saw Machines

We make and sell blades to fit all cold saw machines. On...

-

Cold Saw Blades for JET Cold Saw Machines

We make and sell blades to fit all cold saw machines. On...