Useful Information for Using Your Cold Saw Blades

Can You Use a Diamond Blade for Metal Cutting?

Can you use a diamond blade for metal cutting? Yes, and it might save you money. Discover the safety and performance benefits of diamond blades over abrasives.

Can You Use a Diamond Blade for Metal Cutting?

Can you use a diamond blade for metal cutting? Yes, and it might save you money. Discover the safety and performance benefits of diamond blades over abrasives.

Tips for Reducing Downtime in Your Metal Fabric...

Discover practical tips to reduce downtime in your metal fabrication shop. Boost efficiency and profitability with proactive maintenance and strategic planning.

Tips for Reducing Downtime in Your Metal Fabric...

Discover practical tips to reduce downtime in your metal fabrication shop. Boost efficiency and profitability with proactive maintenance and strategic planning.

How To Solve the Challenges of Machining Inconel

Inconel is an incredible material but presents problems for regular machining. Use these tips for successfully machining Inconel in your workshop.

How To Solve the Challenges of Machining Inconel

Inconel is an incredible material but presents problems for regular machining. Use these tips for successfully machining Inconel in your workshop.

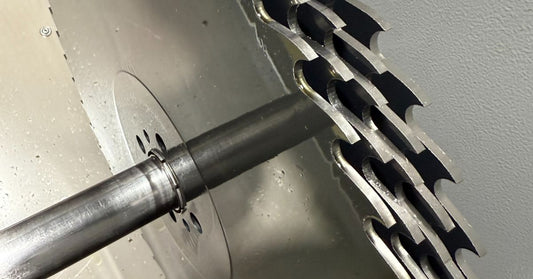

7 Common Errors People Make Using Cold Saws

Cold saws are powerful tools, so it’s easy to make mistakes when using them. Learn how to avoid common errors to improve cut quality, blade life, and safety.

7 Common Errors People Make Using Cold Saws

Cold saws are powerful tools, so it’s easy to make mistakes when using them. Learn how to avoid common errors to improve cut quality, blade life, and safety.

Cold Saw vs. Chop Saw: What Are the Differences?

Each type of saw offers metalworkers numerous benefits. When deciding between a cold saw and a chop saw, knowing the differences can be very helpful.

Cold Saw vs. Chop Saw: What Are the Differences?

Each type of saw offers metalworkers numerous benefits. When deciding between a cold saw and a chop saw, knowing the differences can be very helpful.

A Complete Guide to Cutting Titanium and Its Al...

Certain metals require more planning before cutting through them. You need to know what you’re dealing with when cutting titanium and its alloys.

A Complete Guide to Cutting Titanium and Its Al...

Certain metals require more planning before cutting through them. You need to know what you’re dealing with when cutting titanium and its alloys.