Useful Information for Using Your Cold Saw Blades

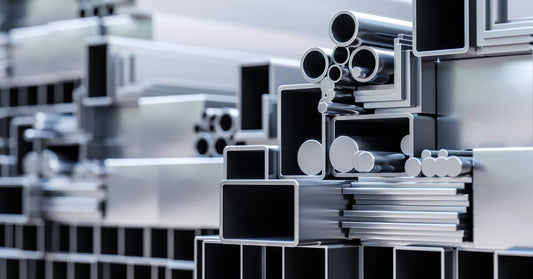

5 Essential Tools To Have When Cutting Aluminum

Metalworkers need the right tools to get their job done. These are the essential items that you should get for cutting aluminum before starting a project.

5 Essential Tools To Have When Cutting Aluminum

Metalworkers need the right tools to get their job done. These are the essential items that you should get for cutting aluminum before starting a project.

6 Tips for Cutting Stainless Steel Effectively

Stainless steel can be a challenging metal to slice through, but there are ways you can handle the task more effectively. Here are our top tips.

6 Tips for Cutting Stainless Steel Effectively

Stainless steel can be a challenging metal to slice through, but there are ways you can handle the task more effectively. Here are our top tips.

Benefits of Working With Carbide-Tipped Cutting...

Your professional metalworking projects require the best tools you can find. Carbide-tipped cutting tools offer many benefits for diverse applications.

Benefits of Working With Carbide-Tipped Cutting...

Your professional metalworking projects require the best tools you can find. Carbide-tipped cutting tools offer many benefits for diverse applications.

Top Trends To Watch For in Metal Fabrication

The world of metal fabrication is evolving just like every other industry. To stay successful, keep up with these top trends that we’re seeing matter.

Top Trends To Watch For in Metal Fabrication

The world of metal fabrication is evolving just like every other industry. To stay successful, keep up with these top trends that we’re seeing matter.

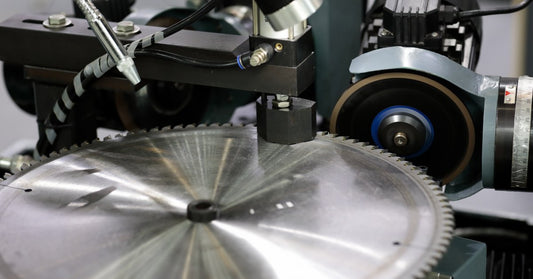

Signs It’s Time To Replace or Sharpen Your Saw ...

Before you embark on metalworking projects, you need to make sure your saw blade is in good shape. Here are the signs you need to replace or sharpen it.

Signs It’s Time To Replace or Sharpen Your Saw ...

Before you embark on metalworking projects, you need to make sure your saw blade is in good shape. Here are the signs you need to replace or sharpen it.

15 Issues To Watch for With Carbide-Tipped Saw ...

Working with carbide-tipped saw blades can provide you with incredible results, but you need to know how to avoid some common issues. Here's what to watch for.

15 Issues To Watch for With Carbide-Tipped Saw ...

Working with carbide-tipped saw blades can provide you with incredible results, but you need to know how to avoid some common issues. Here's what to watch for.