The Benefits of Preventative Maintenance in Metal Cutting

Imagine this: you’re halfway through an important metal cutting project, and suddenly your saw blade breaks down. Deadlines are looming, the pressure is mounting, and your equipment just won’t cooperate. You scramble to find a fix, but the lost time and unexpected costs are already throwing your schedule off track. This frustrating scenario is all too common in workshops that overlook routine maintenance.

The benefits of preventative maintenance in metal cutting are undeniable. It keeps your equipment in peak condition, reduces costly errors, and ensures smooth operations day after day. It’s one of the smartest ways to maximize efficiency and avoid downtime in metal cutting.

Avoid Breakdowns

A dull saw blade, a clogged system, or an improper alignment can grind your workflow to a halt, creating chaos, delays, and even unsafe work conditions. When your tools aren’t functioning properly, every project becomes a struggle, deadlines get pushed back, and frustration builds. What’s worse, equipment failure can lead to costly repairs, damaged materials, or even workplace injuries that no team can afford.

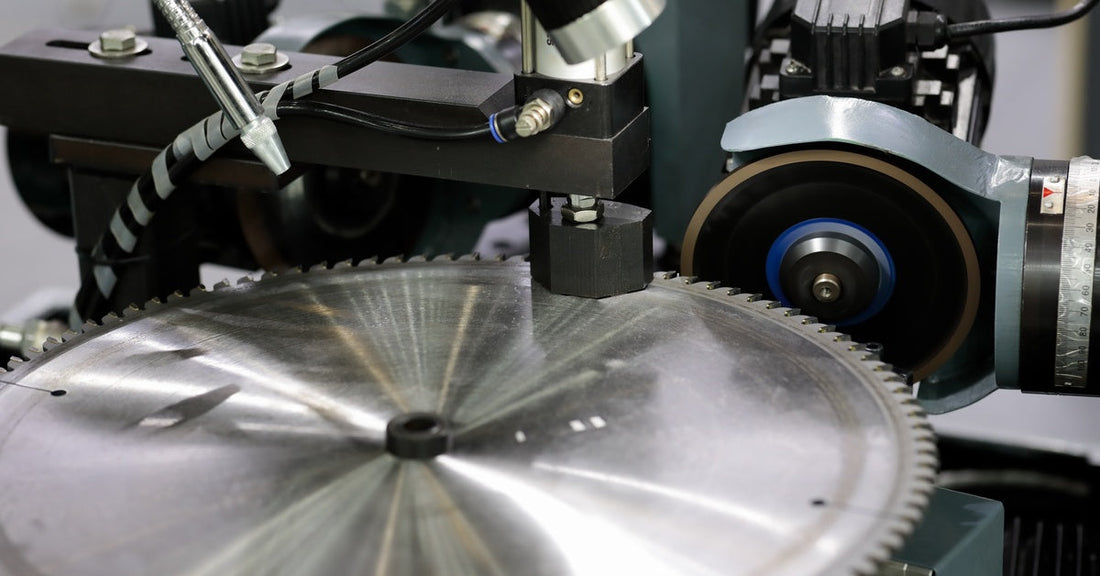

Preventative maintenance eliminates these concerns by addressing small issues before they escalate into major mishaps. Regular care, such as cleaning saw components to prevent buildup, inspecting alignment to ensure precision, and sharpening blades to maintain cutting efficiency, can make all the difference. These simple tasks extend your equipment’s lifespan, improve the quality of your work, and save you significant time and money in the long run.

With a solid maintenance routine in place, you can avoid inconvenient stops mid-task, saving yourself from moments of panic and unnecessary stress. You’ll also be able to work with greater confidence, knowing your equipment is ready when you need it most.

Lower Costs

Every lost hour caused by equipment failure eats into your bottom line. Not to mention, replacing broken parts or machinery can cost a small fortune if the damage is too severe.

Investing in preventative maintenance significantly reduces these expenses by identifying potential problems early on. You spend a fraction of the cost on maintenance now to save exponentially more on expensive repairs or replacements later.

For instance, a well-maintained, sharp saw blade will last longer and cut more effectively than a neglected blade. When you maximize your blade’s usability, you reduce the frequency of replacements, keeping more money in your pocket. This cost-saving approach is sure to set you up for success.

No Unplanned Downtime

Few things are as frustrating as missing deadlines due to equipment failing at the wrong moment. When saws or other essential tools stop working, your entire operation comes to a standstill. Materials pile up, orders fall behind, and your productivity takes a hit while you wait for repairs or replacements to get back on track. Unplanned downtime not only disrupts your workflow but can also damage your reputation with customers and create unnecessary stress for your team.

You can avoid much of this with preventative maintenance. Scheduling regular checks, cleaning, and blade sharpening will keep your equipment in optimal condition for peak performance. With well-maintained equipment, you’ll feel confident taking on large or time-sensitive projects without worrying about interruptions. Instead of reacting to problems at the worst possible time, you can tackle them before your work grinds to a halt.

This proactive mindset not only boosts productivity but also helps your team stay focused and efficient, ensuring every deadline is met without unnecessary downtime.

More Efficient Use of Time

A dull blade may appear to “get the job done,” but it wastes time and compromises quality. The extra effort to push a dull blade through materials slows you down. It also increases the risk of mistakes, uneven cuts, and wasted materials, which could lead to unnecessary rework. Over time, this inefficiency adds up and can significantly impact productivity.

A sharp blade reduces resistance, allowing you to glide through tasks quickly and with minimal effort. This not only helps you complete projects faster but also ensures cleaner, more accurate cuts, giving your work the professional finish it requires.

Regularly sharpening and aligning your blades maintains optimal performance, making every cut smoother and more precise. This simple yet crucial maintenance step reduces unnecessary delays and ensures your workspace operates at its best.

Safer Working Conditions

Poorly maintained tools create dangerous situations that can compromise the health and safety of your team. For example, a dull blade requires significantly more force to cut, increasing the likelihood of slipping or snapping unexpectedly during use. This puts the user at risk of serious injuries that could have been easily avoided. Similarly, clogged components or misaligned machinery can malfunction at critical moments, causing accidents that jeopardize the operator’s safety and the entire work environment.

By ensuring tools are sharp, clean, and properly aligned, you reduce the chances of malfunction and injury. Regular upkeep allows equipment to perform as designed, giving workers the confidence to focus on tasks rather than worrying about potential hazards. It also promotes a culture of responsibility and care, showing your team that their well-being is a top priority.

Extended Lifespan

Finally, a major benefit of preventative maintenance in metal cutting is that it reduces natural wear and tear. This means you won’t have to frequently replace high-ticket items like saws or other machinery.

The longer your tools and machinery last, the greater the return on investment. Instead of retiring tools after just a handful of uses, you’ll be amazed at how well they continue to perform even years down the line. This longevity means you can reinvest savings into other areas of your business, like upgrading technology or expanding operations, creating more opportunities for growth and success.

Reap These Benefits With Professional Services

To fully maximize your metal cutting equipment, we highly recommend getting your blades regularly sharpened. Dull blades slow you down, increase costs, compromise safety, and shorten the lifespan of your tools.

At Cold Saw Shop, we specialize in cold saw blade sharpening that restores your tools to peak performance. Our expert services ensure your machinery performs at its best, giving you the edge you need to cut smarter, faster, and safer. Contact us today to schedule sharpening.