3 Reasons To Sharpen Your Cold Saw Regularly

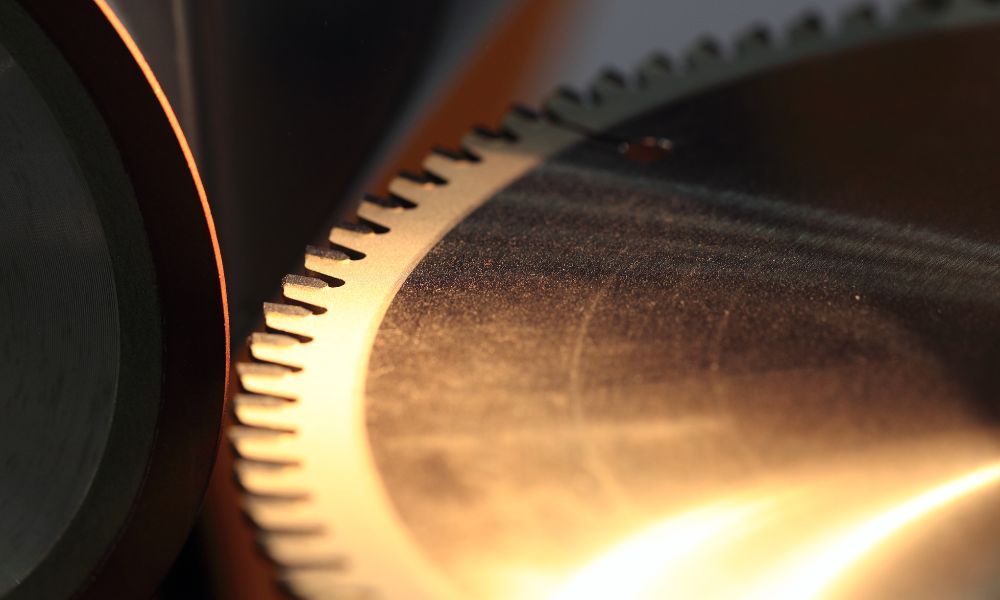

The cold saw is one of the most essential tools in a workshop. It efficiently cuts through metal and other rigid materials, making it a must-have for any craftsman or woodworker. However, like any tool, it requires regular maintenance to ensure its optimal performance. That means sharpening it as needed. Below, we’ve detailed the reasons for sharpening your cold saw regularly.

1. Ensures Precise and Efficient Cuts

A dull blade is the adversary of precision. It requires more force to push through the material, leading to inaccuracies and uneven finishes that can compromise the quality of your projects.

When utilizing a well-sharpened blade, cutting through metal becomes effortless, guaranteeing clean, precise, and consistent cuts. Moreover, sharp blades reduce the amount of effort necessary to make a cut, which speeds up the production process and enhances efficiency.

2. Keeps Machine Operation Safe

Another crucial reason to sharpen your cold saw regularly is to enhance the operator’s safety. A dull blade can cause kickbacks, which are extremely dangerous and can result in serious injuries. Kickbacks occur when the blade gets stuck in the material and flies back toward the operator at high speed. This puts not only the operator at risk but also those around them.

On the other hand, a sharp blade minimizes these risks by cutting smoothly without the need for excessive force or pressure that could destabilize the machine. As a result, the operator can work more confidently, knowing they haven’t compromised their safety.

3. Helps Maintain Your Saw

The strain a dull blade puts on a cold saw goes beyond safety concerns. It can also wear down your machine over time. When a saw isn’t sharp, the motor must work harder to achieve the same cuts, which can lead to overheating and premature component wear. Regular sharpening ensures that your saw operates under optimal conditions, extending its lifespan and reducing the likelihood of costly repairs or replacements.

Pro Tip

By taking care of your cold saw blades, you help them last longer. Maintenance also helps you save money by preventing unnecessary blade replacements. By extending the lifespan of your tools, you’ll also get a better return on your investment.

Hire a Professional Sharpening Service

While it might feel tempting to sharpen your blades in-house, avoid it. Sharpening a cold saw blade requires specialized skills and equipment that only a professional service can provide. If you don’t know the essential techniques, you risk damaging your blade.

Professionals have the expertise and equipment necessary for effective cold saw blade sharpening. They can also identify and rectify any issues with your blades before they become significant problems.

Contact Cold Saw Shop

Regularly sharpening your cold saw blades is a critical practice that you should always pay attention to. Cold Saw Shop offers a professional sharpening service for all types of cold saw blades. Contact us today to schedule your blade sharpening and keep your workshop running smoothly!