ITEM #M312540TLN

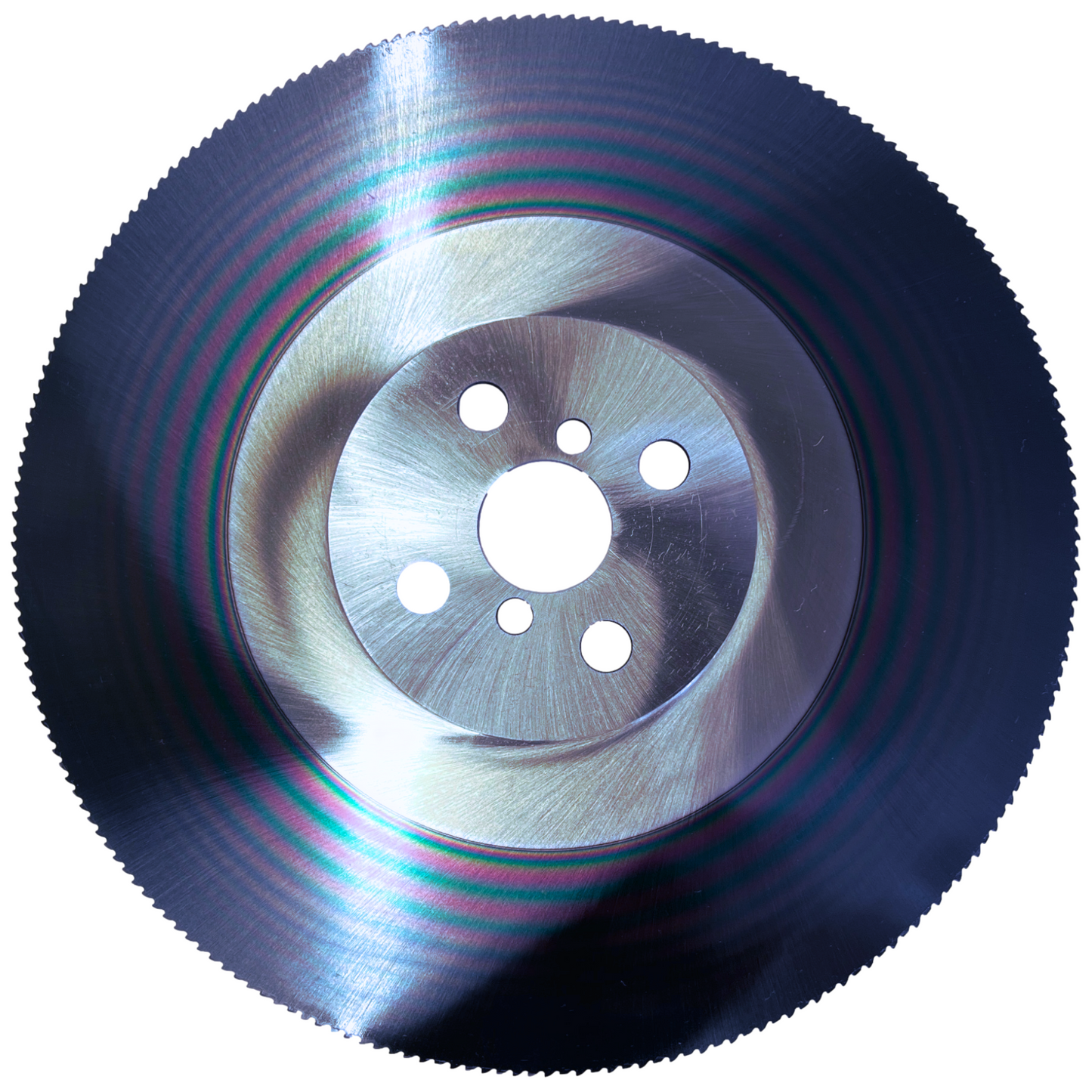

315 x 2.5 x 40 M35 Co5 TiAlN Cold Saw Blade

315 x 2.5 x 40 M35 Co5 TiAlN Cold Saw Blade

Couldn't load pickup availability

Super High-Speed Steel M35 Co5 HSS Titanium Aluminum Nitride (TiAlN/AlTiN) PVD Coated

315MM (12.402”) DIAMETER

2.5MM (0.098”) THICKNESS

40MM (1.574”) ARBOR HOLE

Please verify you order the correct arbor hole size.

If your machine takes a 315mm diameter blade AND has a 40mm arbor, this blade is guaranteed to have the appropriate bolt holes to fit your machine with no issues. Most cold saw machines will have a model number such as CS-315, which will signify the diameter of the blade that the machine uses.

BOLT HOLES: 4/12/64 + 2/9/55

(4/12/64 = 4 bolt holes which are 12mm in diameter on a 64mm bolt circle) The bolt circle is the distance from the center of one pinhole to the center of the other pinhole directly across the arbor hole

If you are unsure of how many teeth you need for your application, try using our tooth count calculator by clicking here (new window or tab will open).

HSS M35 Co5 COBALT BLADES

This blade is made from M35 tool steel containing 5% cobalt in addition to the alloy elements already present in the standard M2 blades. They are considered super high-speed steel blades which will provide extra hardness (66 HRc) for cutting stainless steel and hard alloy steels above 800 N/mm².

This is the ultimate TiAlN Coated cold saw blade. It will outperform and outlast others. Our M35 TiAlN Coated blade contains 5% cobalt, which makes it an M35 Co5 blade. As a result, it is harder and more durable than a standard M2 blade.

TITANIUM ALUMINUM NITRIDE PVD COATED

Titanium Aluminum Nitride (TiAlN) delivers the highest temperature-resistant coating available. Violet in color, TiAlN provides a high degree of surface hardness, making it a good choice for uninterrupted cuts. For this reason, this coating is usually recommended for production sawing or for customers who are having a hard time with blade life when cutting stainless steel, titanium alloys, Inconel, cast iron, and more.

All blades are ground in the US on advanced computer numerically controlled (CNC) grinding equipment made specifically for manufacturing our blades to our specific standards by industry experts with over 40 years of industry experience.

MACHINES THIS BLADE WILL MOUNT TO

- Doringer D300 with 315mm conversion

- Haberle H300 (max blade diameter 315mm)

- KAKA CS-12

- Scotchman CPO 315 HFA

- Woodward Fab 315

- AND More! Unsure? Call or email us!

Q&A

Reviews

- Choosing a selection results in a full page refresh.

- Opens in a new window.