Everything You Need To Know About Cutting Aluminum

Cutting aluminum is a task that requires precision, knowledge, and the correct tools. If you're a professional in the metal industry, understanding the intricacies of this process can enhance your efficiency and ensure the longevity of your equipment. This informative guide will explain everything you need to know about cutting aluminum.

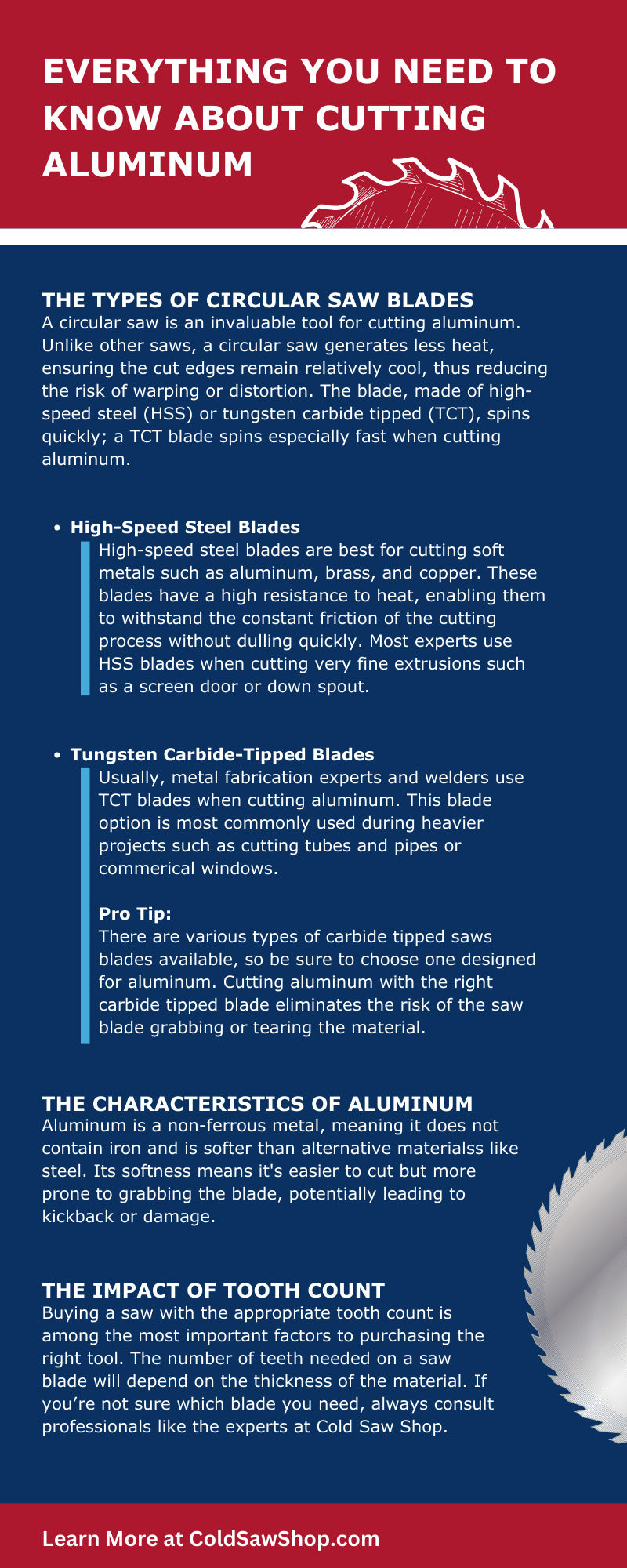

The Types of Circular Saw Blades

A circular saw is an invaluable tool for cutting aluminum. Unlike other saws, a circular saw generates less heat, ensuring the cut edges remain relatively cool, thus reducing the risk of warping or distortion. The blade, made of high-speed steel (HSS) or tungsten carbide tipped (TCT), spins quickly; a TCT blade spins especially fast when cutting aluminum.

High-Speed Steel Blades

High-speed steel blades are best for cutting soft metals such as aluminum, brass, and copper. These blades have a high resistance to heat, enabling them to withstand the constant friction of the cutting process without dulling quickly.

HSS blades are ideal for cutting aluminum because they can maintain their sharpness even when running at high speeds. Most experts use HSS blades when cutting very fine extrusions such as a screen door or down spout.

Tungsten Carbide-Tipped Blades

Usually, metal fabrication experts and welders use TCT blades when cutting aluminum. This blade option is most commonly used during heavier projects such as cutting tubes and pipes or commercial windows.

Pro Tip

There are various types of carbide tipped saws blades available, so be sure to choose one designed for aluminum. Cutting aluminum with the right carbide tipped blade eliminates the risk of the saw blade grabbing or tearing the material.

The Characteristics of Aluminum

Aluminum is a non-ferrous metal, meaning it does not contain iron and is softer than alternative materials like steel. By using the wrong blade, you risk ripping the material, which will leave a poor cut and could dull your blade. To prevent this, ensure you use sharp circle saw blades when cutting a piece of aluminum.

The Impact of Tooth Count

Buying a saw with the appropriate tooth count is among the most important factors to consider when purchasing the right tool. Although buying a saw with more teeth may seem ideal, this isn’t always the case.

The number of teeth needed on a saw blade will depend on the thickness of the material. If you’re not sure which blade you need, always consult professionals like the experts at Cold Saw Shop.

The Importance of Safety

Always wear safety glasses to protect your eyes from flying debris produced during cutting. Moreover, saw operators should wear ear protection as circular saws can be loud, and long-term exposure can impact hearing. In addition to eye and ear protection, all saw operators should wear:

- Protective gloves to prevent cuts from sharp edges

- A face shield or mask to protect from coolant mist

- Protective clothing to avoid any contact with the blade

Additionally, when cutting a piece of aluminum, you may need to feed it to the saw; in this instance, your fingers should remain at least six inches from the blade.

The Cut Preparation Process

Before cutting aluminum, ensure you set your saw up correctly—blade height and angle adjustments can significantly affect the quality of your cut. To determine the proper height, place a piece of aluminum on the workbench and adjust the blade until it's just above the metal's surface.

Pro Tip

Invest in a reliable measuring tool, such as a steel ruler or a digital caliper, and always double-check your measurements before cutting.

Ways To Make Cutting Aluminum Efficient

Additional things you need to know about cutting aluminum include:

- Using lubricant

- Understanding blade speeds

- Utilizing quality tools

- Maintaining all equipment

- Clamping your aluminum

Following these tips makes it easier to achieve quality cuts, minimize blade wear, and increase efficiency. We've detailed various ways to make the cutting process effective in the below sections.

Using Lubricant in Cutting Aluminum

As a soft, non-ferrous metal, aluminum may stick to the saw blade during cutting, causing what's known as chip welding. This can lead to rough cuts and even damage your tools over time.

Applying a lubricant reduces this risk, creating a barrier between the aluminum and the blade, allowing for smoother movement and cleaner cuts. Moreover, it helps dissipate the heat generated during cutting, protecting your workpiece and tools from potential thermal damage.

Pro Tip

Review the manufacturer's recommendations if you're unsure what type of lubricant is best for your blade. Companies such as Cold Saw Shop sell wax sticks for cutting aluminum that work perfectly with our saw blades.

Buying Quality Tools in Aluminum Cutting

When it comes to this asset, businesses often invest in better quality equipment; it pays off overall. Some saw blades may appear more expensive, but they're often worth the price as they can last significantly longer and provide better results. Moreover, using top-quality blades and saws can reduce maintenance and repair costs since they take longer to dull.

High-quality tools can also withstand the demands of cutting non-ferrous metals like aluminum, providing better performance and longevity. As you evaluate your business budget, set aside an appropriate amount of money into tools and equipment that will last through years of regular use.

Pro Tip

When shopping for circular saw parts, choose reputable brands and suppliers that will provide top-quality materials for your equipment. You should also read customer reviews on a product and brand to verify quality.

Maintain Your Cutting Tools

Regularly clean and inspect your tools for any signs of wear or damage. Keep blades sharp and replace them when necessary, as dull blades can cause rough cuts or damage your workpiece. Some companies selling saw blades also offer sharpening services that help users keep their tools in optimal condition without needing constant replacement.

In addition to having a professional sharpen your saw blades, you should have the manufacturer evaluate the saw itself annually. During inspections, they can check for potential damage to the equipment and discuss any necessary repairs before you use the saw again.

Clamp Aluminum Sheets

If you cut an aluminum sheet, it’s best to clamp it in place to prevent it from moving during the process. You can use standard woodworking clamps as well as a vise to secure the sheet firmly in place; some experts also use a routing table to keep the metal in place.

Shop at Cold Saw Shop

Cutting aluminum efficiently allows you to turn out quality work anytime you need to work with the material. Cold Saw Shop offers a selection of high-quality aluminum cutting saw blades in a range of sizes to meet the needs of professionals. With quality blades and knowledge of how to cut aluminum, you'll be well on your way to achieving perfect cuts every time.