10 Advantages of a Carbide-Tipped Saw Blade

Metalworkers have access to a wide range of tools and blades when it comes to performing their work. Everyone from seasoned professionals to those new to the craft should have a variety of blades that can handle different types of metal or specific items.

Cold Saw Shop wants to teach you about ten advantages of a carbide-tipped saw blade. Blades have many different potential coatings, but this is one of the most common, versatile, and a good option for every workshop. Having a carbide-tipped blade readily available can help you perform high-quality work on a wide range of projects.

What Are Carbide-Tipped Saw Blades?

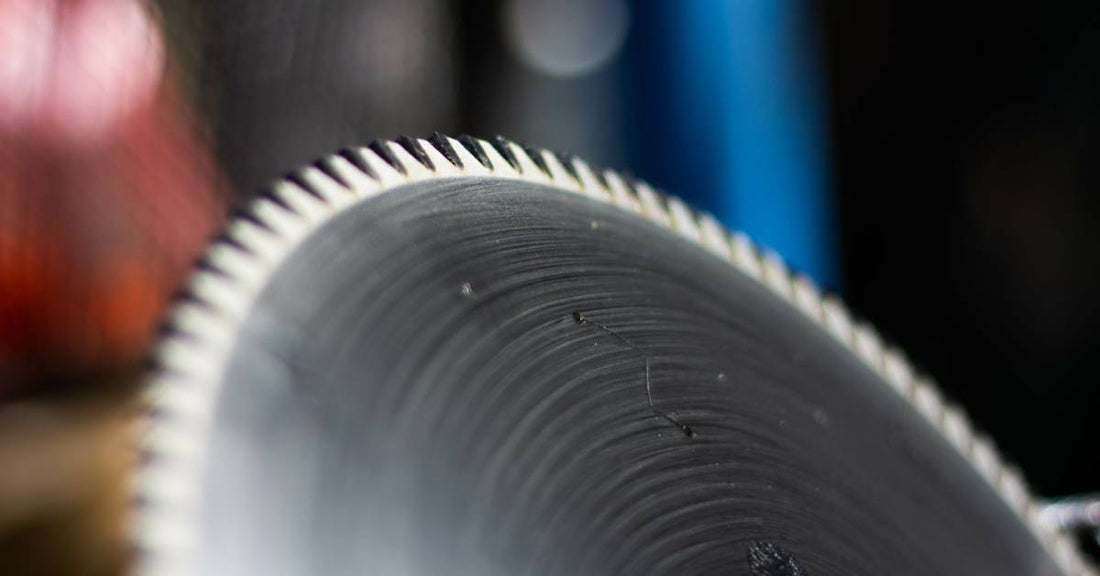

Carbide-tipped saw blades are beneficial tools for enhancing cutting efficiency and durability. Unlike traditional saw blades, which typically contain only a single material, these blades feature carbide, a very hard material composed of carbon and additional metals such as tungsten, titanium, or tantalum.

Their distinct composition allows for exceptional hardness and heat resistance, making carbide-tipped blades ideal for cutting through tough metals. Manufacturers braze the teeth of the steel blade with carbide tips, allowing them to maintain sharpness for a longer period, leading to improved cutting performance and a longer lifespan compared to standard steel blades. This unique construction makes them a popular choice among professionals who require precision and reliability in their cutting tasks.

Superior Durability

One of the biggest advantages of carbide-tipped saw blades is their superior durability. These blades stand out because their carbide tips are incredibly wear-resistant, extending the blade's life and reducing the frequency of replacements. This is especially beneficial when working with abrasive materials such as metal, which can cause other blades to quickly dull or break down.

The carbide allows these blades to withstand higher temperatures and resist cutting-induced stress, ensuring sustained performance under rigorous conditions. The longevity of carbide-tipped blades means fewer interruptions during projects, enhancing operational efficiency and saving time and money in the long run. Their impressive durability makes them an invaluable tool for hobbyists and professionals who undertake regular cutting tasks.

Enhanced Cutting Precision

Professionals looking for enhanced cutting precision can find that with carbide-tipped blades. Circular saw aluminum cutting blades with the extra carbide coating around the teeth help maintain a sharp edge through extensive use and delivery smooth, clean cuts. Cutting through tougher metals often leaves jagged edges or burrs in the cutting process, so you want to make sure you’re using a precise blade that cuts straight through without struggling or overheating.

This precise cutting ability is crucial when working on projects that demand high levels of accuracy in your metalwork. The consistent sharpness of carbide-tipped blades allows for smoother operation with less vibration, reducing the chance of errors and material wastage. This precision not only ensures high-quality results but also contributes to greater control and safety during cutting tasks, making carbide-tipped saw blades an essential choice for anyone looking to achieve flawless outcomes in their work.

Increased Efficiency

Carbide-tipped saw blades significantly boost cutting efficiency, offering numerous advantages for metalworkers, construction professionals, and anyone else who relies on cutting through tough materials. Their unique composition and design allow for faster cutting speeds, which can dramatically reduce the time spent on tasks.

The ability of carbide tips to maintain sharpness longer than traditional blades means that workers can complete cuts more swiftly and with less effort to reduce operator fatigue. This increased efficiency not only accelerates project timelines but also enhances productivity, allowing workers to focus on finer details or additional tasks.

Reduced Downtime

Having to regularly replace blades throughout a project significantly reduces the amount of downtime experienced by metalworkers throughout the project. Carbide-tipped saw blades reduce the need for constant maintenance and replacement, as their superior durability ensures they stay sharp for longer. This reduction in downtime means workers can focus more on their tasks and less on tool maintenance, leading to an increase in overall productivity and better scheduling.

Versatility in Metalworking

You can’t look at the advantages of a carbide-tipped saw blade without considering their incredible versatility. These blades are efficient at cutting through a wide range of metals from soft aluminum to hard steel.

This versatility makes them an excellent choice for metalworkers who deal with various materials and need a reliable blade that can handle different tasks. With a carbide-tipped blade, you can tackle a variety of projects without needing to switch tools frequently.

Cost Effectiveness

While carbide-tipped saw blades generally have a higher upfront cost compared to traditional steel blades, they are undeniably more cost effective in the long term. The extended lifespan, reduced need for replacements, and increased efficiency all contribute to significant cost savings over time. Metalworkers looking to optimize their budget without compromising on quality should consider investing in carbide-tipped blades.

Consistent Performance

Consistency is crucial in metalworking, and carbide-tipped saw blades deliver reliable performance throughout their lifespan. Unlike steel blades that can quickly lose their sharpness and effectiveness, carbide-tipped blades maintain their cutting ability for much longer. This consistent performance ensures that you can rely on your tools to deliver high-quality results every time, enhancing your reputation for precision and reliability.

Improved Safety

Safety is always a top priority in any workshop, and carbide-tipped saw blades contribute to a safer working environment. Their ability to maintain sharpness and precision reduces the likelihood of accidents caused by blade failure or improper cuts.

The reduced need for frequent blade changes means fewer opportunities for injury during blade replacement. Workers can create a safer and more efficient workspace by using carbide-tipped circular saw blades.

Ease of Maintenance

Metalworkers appreciate that maintaining carbide-tipped saw blades is a fairly straightforward experience. The durability and resilience of carbide teeth mean that these blades require less frequent sharpening and maintenance compared to steel blades. When workers do need to attend to these blades, it’s a quick and simple process that allows them to get back to their tasks with very little disruption.

Environmental Benefits

Finally, carbide-tipped saw blades offer environmental advantages. Their longer lifespan and reduced need for replacements result in less waste, contributing to a more sustainable approach to metalworking. Additionally, the efficiency and precision of these blades can reduce material wastage, further minimizing their environmental impact.

Cold Saw Shop offers a wide range of carbide-tipped circular saw blades that can help you with your toughest metalworking jobs. We offer blades in a wide range of sizes, materials, and styles to ensure that you can always get what you’re looking for. Feel free to browse our online catalog and contact us anytime if there’s anything specific that we can help you with.