ITEM #353040C5

350 x 3.0 x 40 HSS M35 Co5 Cold Saw Blade

350 x 3.0 x 40 HSS M35 Co5 Cold Saw Blade

Couldn't load pickup availability

350MM (13.779”) DIAMETER

2.5MM (0.098”) THICKNESS

40MM (1.575”) ARBOR HOLE

Please verify you order the correct arbor hole size.

If your machine takes a 350mm diameter blade AND has a 40mm arbor, this blade is guaranteed to have the appropriate bolt holes to fit your machine with no issues. Most cold saw machines will have a model number such as CS-350, which will signify the diameter of the blade that the machine uses.

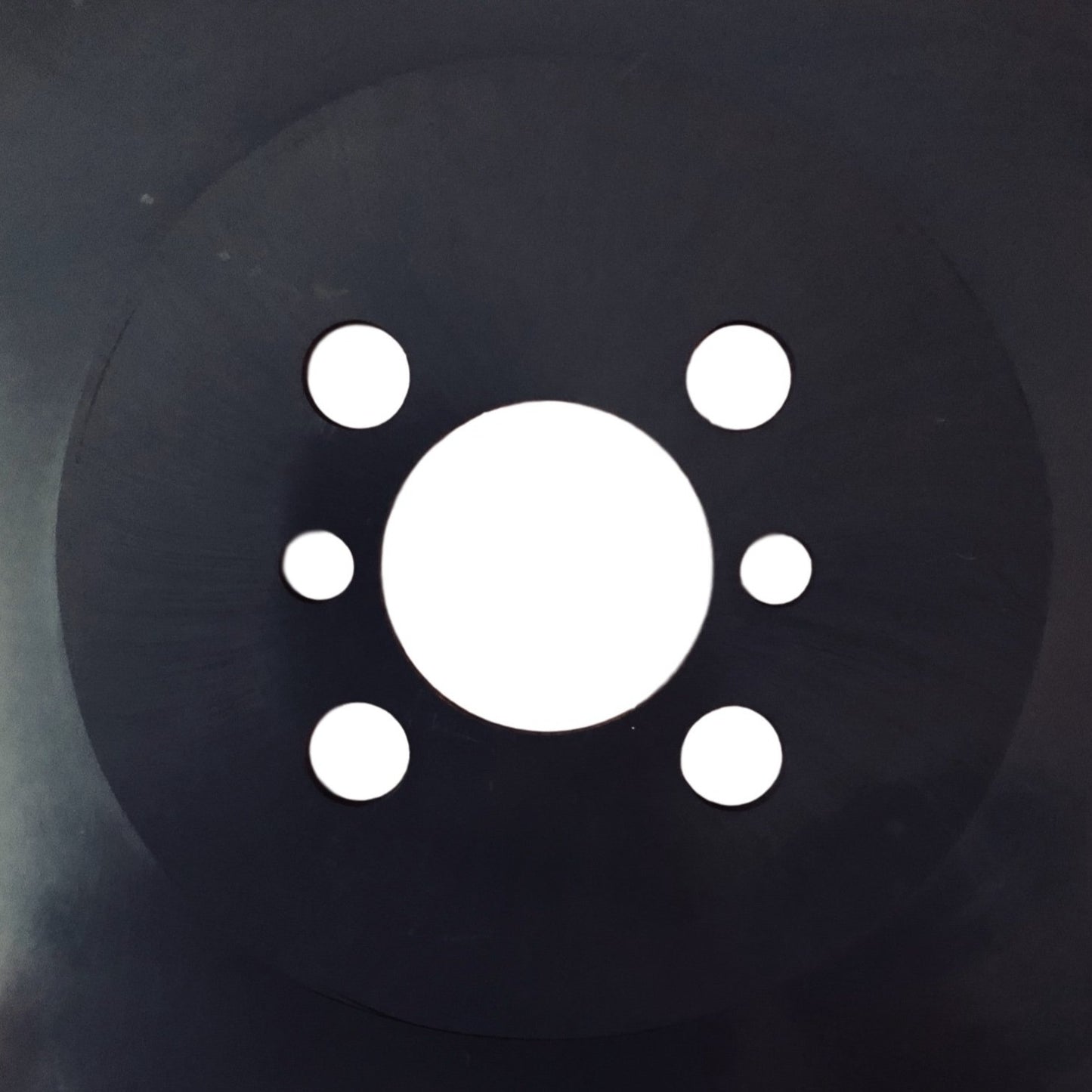

BOLT HOLES: 2/9/55 + 4/12/64

(4/12/64 = 2 bolt holes which are 12mm in diameter on a 64mm bolt circle) The bolt circle is the distance from the center of one pinhole to the center of the other pinhole directly across the arbor hole

If you are unsure of how many teeth you need for your application, try using our tooth count calculator by clicking here (new window or tab will open).

HSS M35 Co5 COBALT BLADES

This blade is made from M35 tool steel containing 5% cobalt in addition to the alloy elements already present in the standard M2 blades. They are considered super high-speed steel blades which will provide extra hardness (66 HRc) for cutting stainless steel and hard alloy steels above 800 N/mm².

Do you think you're going through too many blades or they're dulling too quickly? Try our M35 Co5 blades.

VAPOR STEAM TREATED BLACK OXIDE

All cold saw blades used to cut steel products should have a coating. The most common coating is black oxide, sometimes referred to as vapor steam coated. The coating is most important to help prevent galling. Galling is caused by friction between sliding surfaces, most commonly found in metal on metal applications when there is inadequate lubrication between the surfaces. The combination of the coated blade and your flood coolant will prevent this issue.

All blades are ground in the US on advanced computer numerically controlled (CNC) grinding equipment made specifically for manufacturing our blades to our specific standards by industry experts with over 40 years of industry experience.

MACHINES THIS BLADE WILL MOUNT TO

- Bolton CS-350

- Brobo S350D, SA350

- Doringer D350

- Haberle H350, H90

- Scotchman CPO 350

- AND More! Unsure? Call or email us!

Q&A

Reviews

- Choosing a selection results in a full page refresh.

- Opens in a new window.