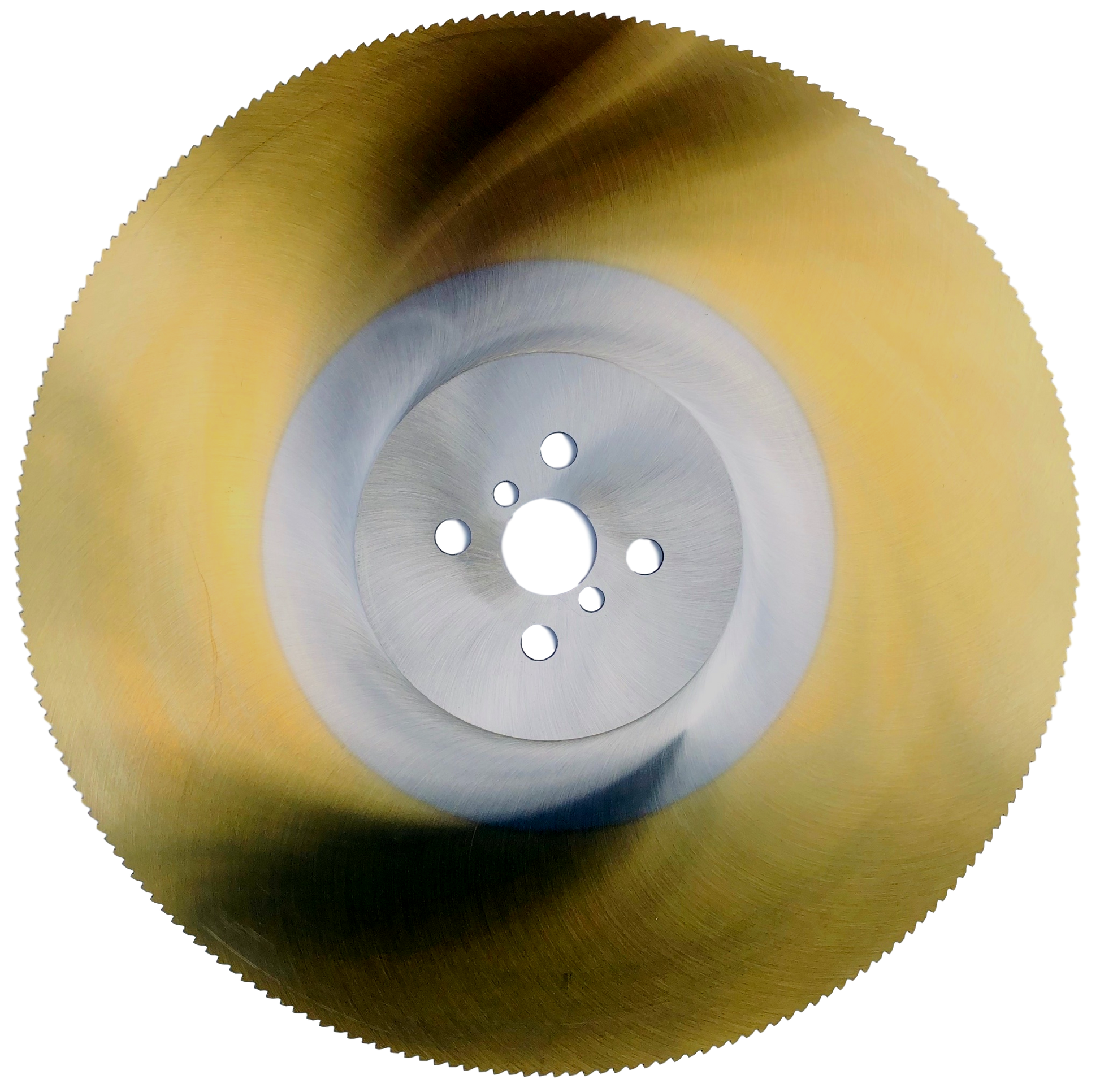

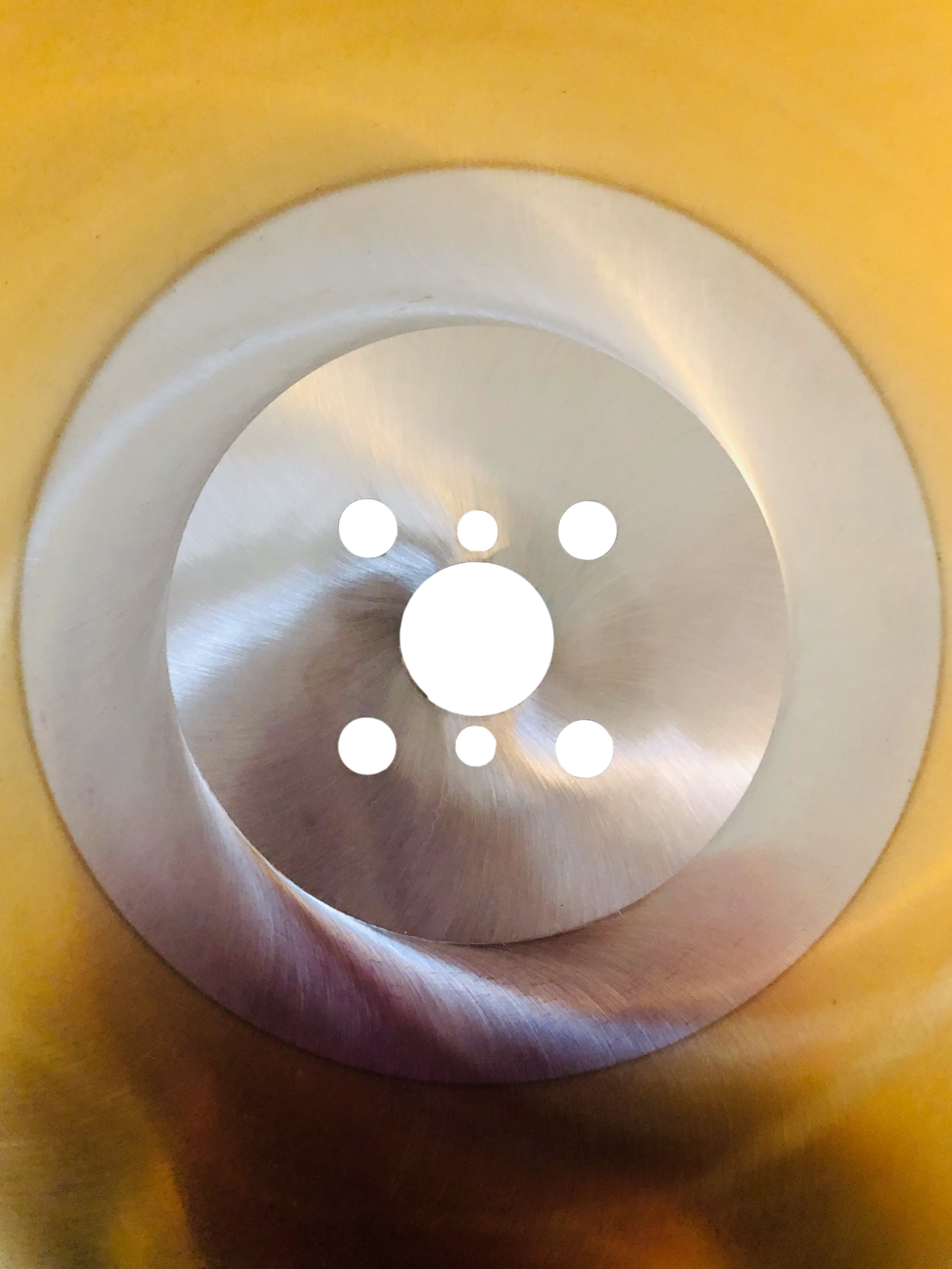

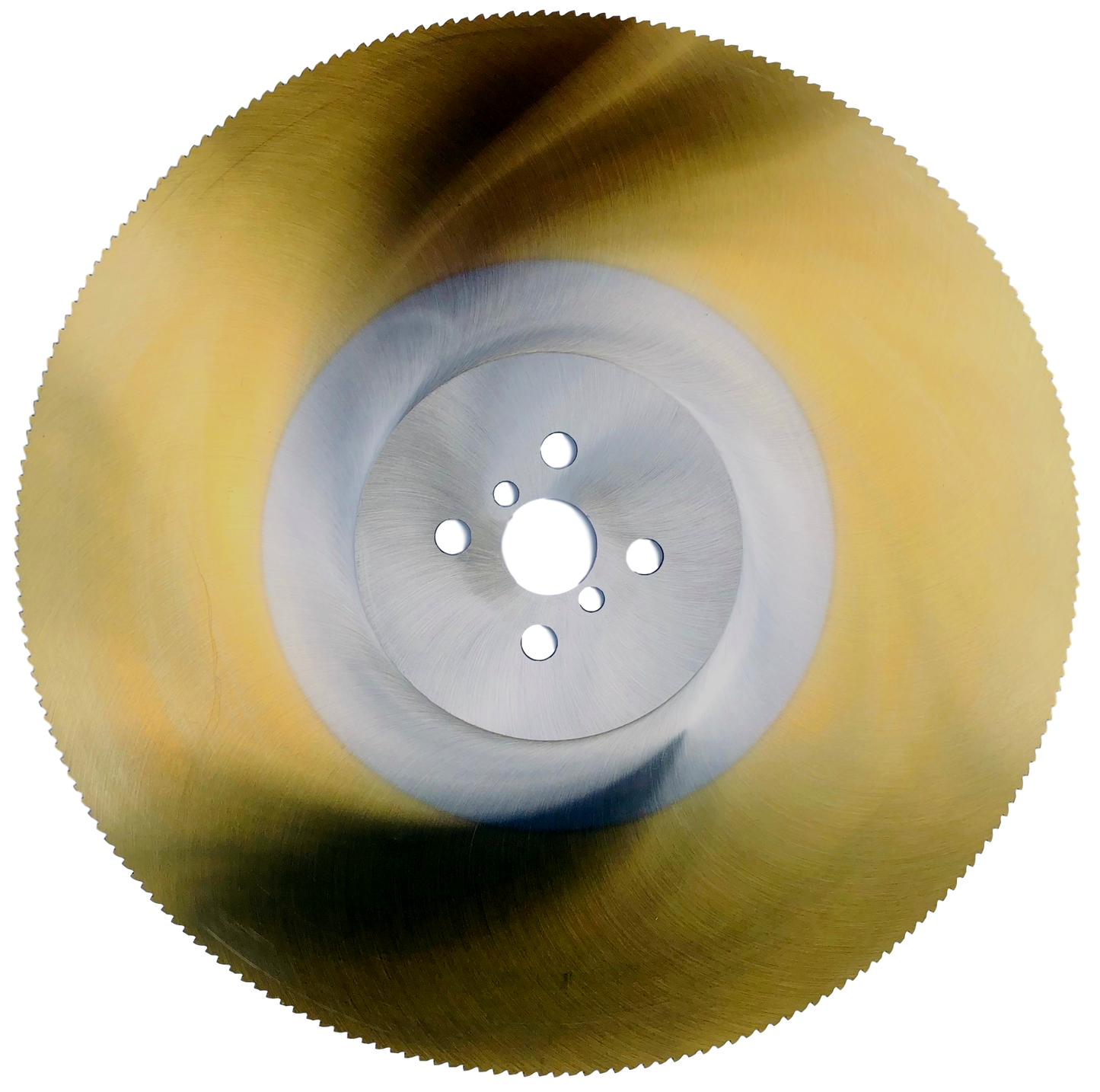

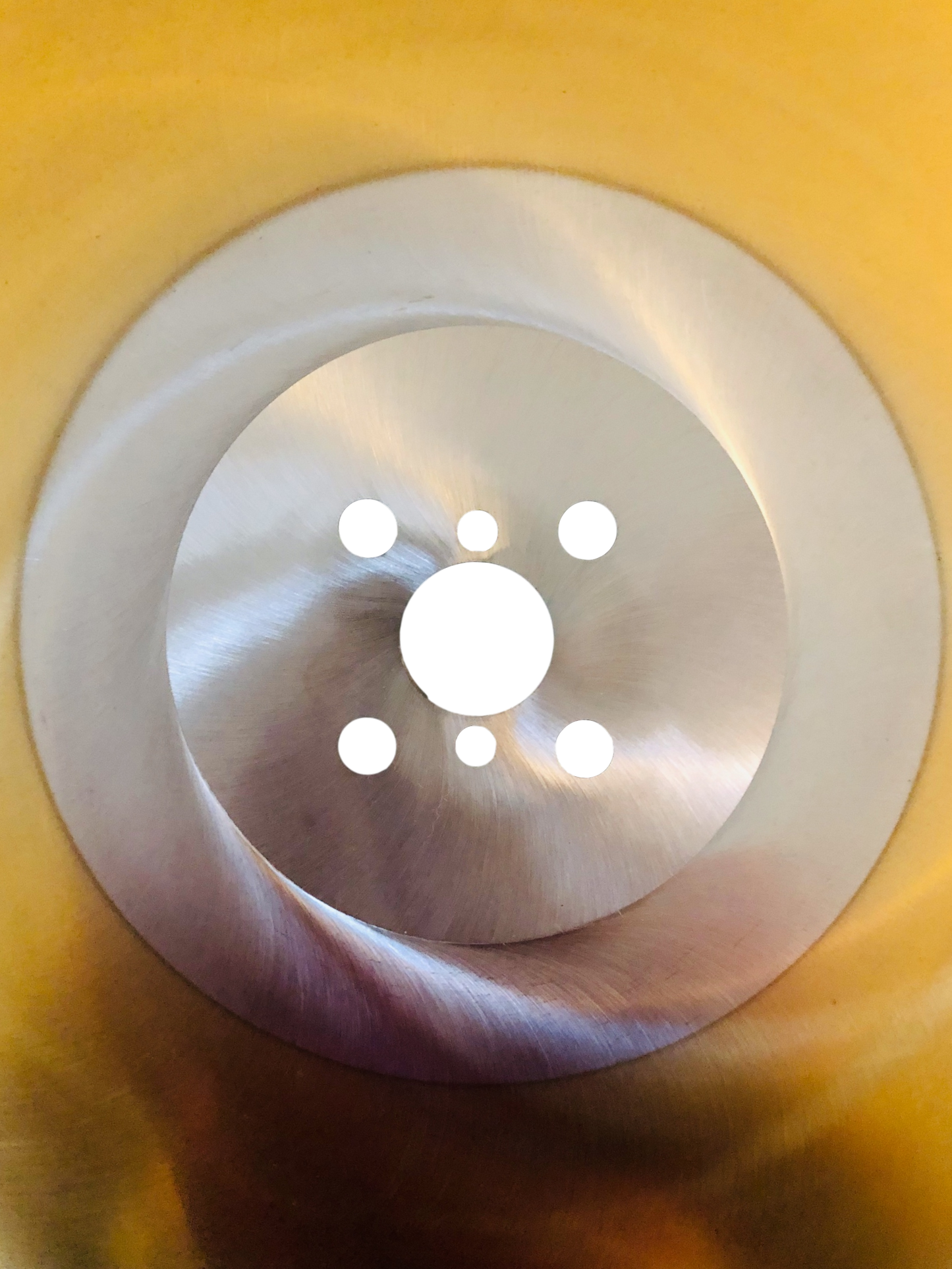

ITEM #252032T

250 x 2.0 x 32 HSS M2 DMo5 TiN Coated Cold Saw Blade

250 x 2.0 x 32 HSS M2 DMo5 TiN Coated Cold Saw Blade

Couldn't load pickup availability

250MM (9.843") DIAMETER

2.0MM (0.078") THICKNESS

32MM (1.256") ARBOR HOLE

Please verify you order the correct arbor hole size.

If your machine takes a 250mm diameter blade AND has a 32mm arbor, this blade is guaranteed to have the appropriate bolt holes to fit your machine with no issues. Most cold saw machines will have a model number such as CS-250, which will signify the diameter of the blade that the machine uses.

BOLT HOLES: 2/11/63 + 2/12/64 + 2/8.5/45

(2/11/63 = 2 bolt holes which are 11mm in diameter on a 63mm bolt circle) The bolt circle is the distance from the center of one pinhole to the center of the other pinhole directly across the arbor hole

If you are unsure of how many teeth you need for your application, try using our tooth count calculator by clicking here (new window or tab will open).

HSS M2 DMo5 COLD SAW BLADES

Our cold saw blades combine HSS (High-Speed Steel) M2 and DMo5 steel, both renowned in manufacturing and machining. HSS M2, enriched with tungsten, molybdenum, vanadium, and carbon, stands out for its toughness and wear resistance at elevated temperatures. It is widely applied in drills, taps, milling cutters, and tool bits necessitating high cutting speeds and temperatures. DMo5, a high-alloy cold-work tool steel or AISI M2 modified, offers exceptional wear resistance, hardness, and toughness crucial for cold work tasks like crafting cutting and punching tools, as well as dies for blanking and forming operations under high stresses. While both materials excel in various machining and cutting scenarios, their integration in cold sawing enhances their performance.

Titanium Nitride (TiN) Coating

Titanium nitride (TiN) coating for cold saw blades is a thin layer of titanium nitride applied to the surface of the blade through a process called physical vapor deposition (PVD). This coating provides several benefits:

- Reduced Friction: TiN coating on the sides of the blade decreases friction between the blade and the workpiece material, promoting smoother cutting action, reducing heat generation, and preventing binding.

- Enhanced Corrosion Resistance: The coating acts as a protective barrier against corrosion and chemical damage, extending the overall lifespan of the blade, especially in harsh cutting environments.

- Improved Chip Ejection: The reduced friction provided by the TiN coating aids in chip ejection, enhancing cutting efficiency and preventing chips from clogging the blade or cutting area.

- Increased Durability: The increased hardness of the TiN coating improves the blade's durability, enabling it to withstand the stresses of cutting operations and reducing the frequency of blade changes, ultimately enhancing performance, longevity, and efficiency in cold sawing applications.

MACHINES THIS BLADE WILL MOUNT TO

- Baileigh CS-250EU

- Bolton CS-250

- Dake Cut 250 (974250)

- Dake Technics 250

- Grizzly T28366

- Knuth KKS T 250 (102119)

- MACC MC-NEW250DV

- Quantum 250 DV

- Rong-Fu RF-250CS

- Thomas 250

- Woodward Fab WFCS250

- AND More! Unsure? Call or email us!

Q&A

Reviews

- Choosing a selection results in a full page refresh.

- Opens in a new window.