How Do Professionals Sharpen Circular Saw Blades?

Keeping your circular saw blades sharp is an important aspect of all metalwork. Whether you aim to do it yourself or seek professional assistance, it helps to understand the basics of the process. If you’ve ever wondered how professionals sharpen circular saw blades, Cold Saw Shop is here to go over our process.

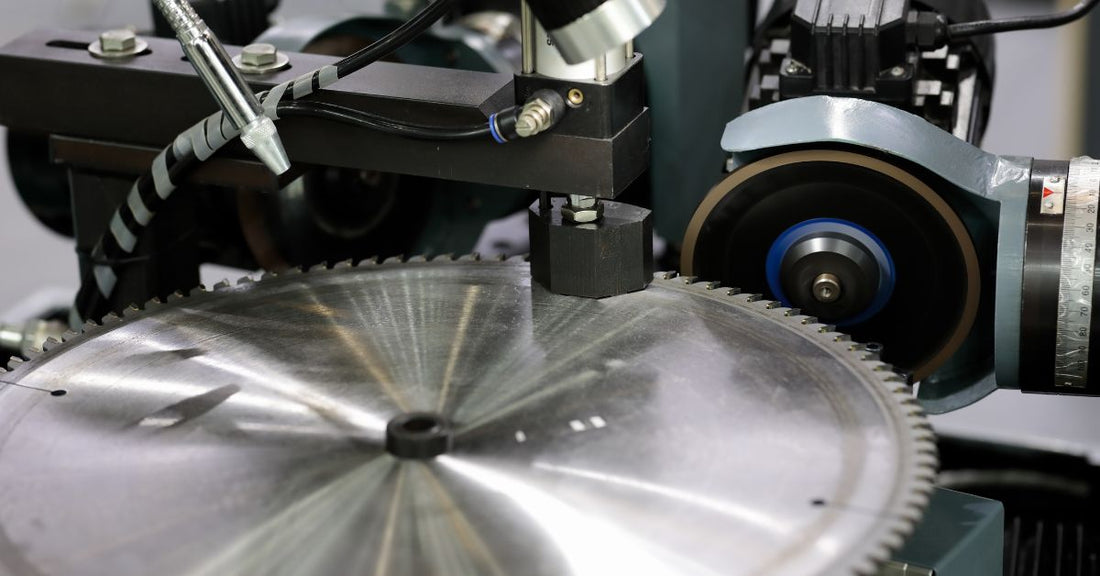

We utilize Loroch sharpening machines and offer these sharpening services for those looking to expand their metalworking capabilities. Learn how we prepare blades for sharpening, how we use these machines, and how these services can benefit you and your tools.

Why Sharp Blades Matter in Metalworking

Sharp saw blades are crucial in metalworking for several reasons. A sharp blade reduces the effort to cut, increasing productivity and reducing wear on both the blade and machine. Sharp blades also enhance the quality of the cut, ensuring the clean and precise edges essential in metalwork applications. Dull blades, on the other hand, can lead to uneven cuts, increased waste, and potential damage to the workpiece. These costly setbacks can cause major problems if you don’t take care of them.

Introduction to Loroch Machines

Loroch machines are synonymous with precision and efficiency when it comes to sharpening and carving out blades for metalworking. This is because they boast advanced technology and robust builds. Loroch blades also come in a wide range of models to create sharp, well-carved teeth in blades.

Loroch machines come with various features that cater to the unique needs of metalworking, including automatic tooth measurement, adjustable speeds, and customizable grinding cycles. Many professionals enjoy the ease and convenience the machines provide. Let’s take a look at how we use them in our sharpening services.

Setting Up the Loroch Machine for Sharpening

Setting up a Loroch machine is the first step in the sharpening process. Professionals start by cleaning the machine and calibrating it to the blade. This process also involves checking the alignment of the grinding wheel, adjusting the speed settings, and securing the blade in place using the machine’s clamps.

Proper setup is an important step that ensures the accuracy of the sharpening process and prevents damage to the blade. After setting up the machine, you must select the appropriate grinding cycle to match your blade’s material and condition.

Understanding the Grinding Process

The grinding process is at the heart of blade sharpening, and Loroch machines excel in this area with their precision engineering. The machine uses a grinding wheel to remove small amounts of material from the blade, effectively restoring its sharp edge.

During this process, you should carefully monitor the grinding wheel’s condition, and replace it when necessary to maintain optimal performance. Take special care to control the grinding speed and pressure to prevent it from overheating or damaging the blade.

The Role of Coolant in Sharpening

Coolant plays a vital role in the sharpening process by preventing overheating and reducing friction between the blade and the grinding wheel. Loroch machines have high-quality coolant systems that keep the blade cool throughout the grinding and sharpening process.

This is particularly important when working with metal blades, as excessive heat can cause warping or structural damage. By maintaining a steady flow of coolant, the Loroch machine protects the integrity of the blade while sharpening.

Safety Protocols During Sharpening

Remember that, when professionals sharpen circular saw blades, they value safety and prep work above all else. When using a Loroch machine, you must always follow the instructions and safety protocols for the model you’re using.

This includes wearing the appropriate personal protective equipment (PPE), such as gloves and eye protection, and ensuring you set all the machine’s safety guards in place. You should never operate a Loroch machine or similar sharpening equipment without proper training or supervision from someone with experience.

Troubleshooting Common Issues

Despite their advanced technology, Loroch machines may occasionally encounter issues during operation. Common problems include uneven grinding, excessive noise, or unexpected stoppages.

Troubleshooting these issues often involves checking the machine’s settings and components for signs of wear or misalignment. If you notice uneven grinding, you may want to recalibrate the machine or replace the grinding wheel. If you hear excessive or unusual noises from the machine, you may need to lubricate it or perform more intricate maintenance.

The Importance of Regular Maintenance

Regular maintenance is crucial to prolonging the lifespan of a Loroch machine and ensuring its continued efficiency. Your maintenance routine should include routine cleaning, lubricating moving parts, and inspecting the grinding wheel and coolant system.

Regular maintenance not only prevents unexpected breakdowns but also enhances the machine’s performance by keeping all components in optimal condition. Keep performance and maintenance records to track the machine’s usage and identify when issues occur.

Benefits of Using a Loroch Machine

There are many fantastic benefits to using a Loroch machine for your cold saw sharpening needs. Naturally, these machines offer a much higher level of precision and consistency compared sharpening by hand or without professional assistance. This translates into improved cutting performance, reduced downtime, and increased productivity for metalworkers.

Secondly, Loroch machines feature intuitive controls and automated systems that simplify the sharpening process, making it safer and more efficient. This makes them accessible to both experienced machinists and newcomers alike.

Lastly, the durability and reliability of Loroch machines make them a cost-effective choice for any metalworking operation, offering long-term value through enhanced efficiency and reduced maintenance costs.

Advancing Your Metalworking Skills

Sharpening saw blades with a Loroch machine is an essential skill for metalworkers seeking to improve their craft. For that reason, it’s no wonder that these machines are a popular choice with professionals who sharpen blades.

The sharpening process requires careful attention to detail, from setup and grinding to maintenance and troubleshooting, but the results are well worth the effort. With the knowledge and insights provided in this post, metalworkers can optimize their sharpening techniques and elevate their skills to new heights.

Don’t let dull blades slow down your metalworking projects. At Cold Saw Shop, we offer a comprehensive circular saw blade sharpening service that will restore your blades to peak performance.

Our expertise with advanced Loroch machines provides precision sharpening that keeps your operations running smoothly. Visit Cold Saw Shop today to learn how we can assist in maintaining your equipment, or contact us to schedule your next sharpening service.