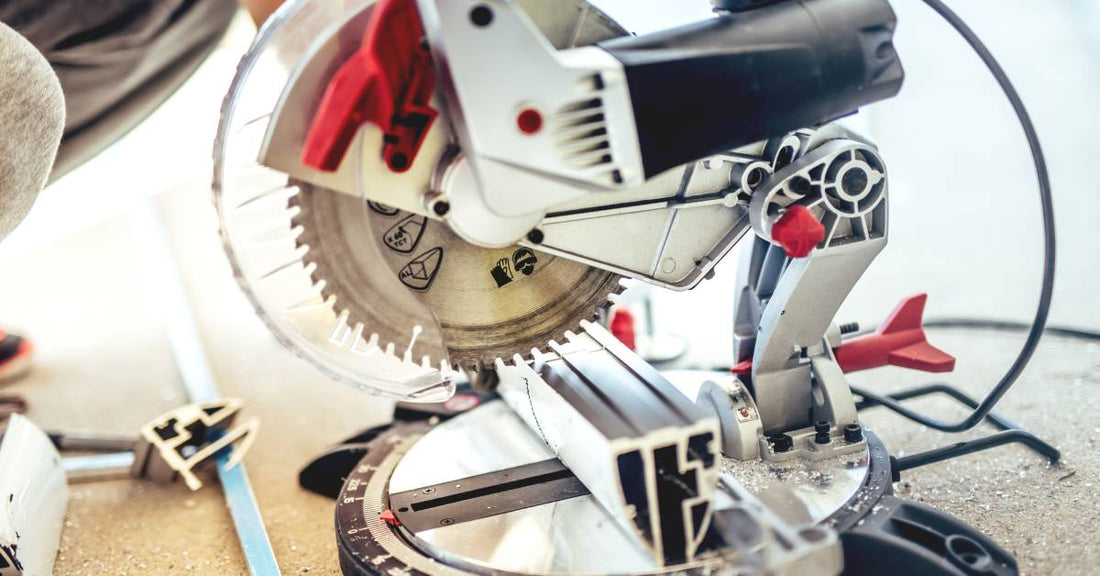

Common Saw Blade Teeth Shapes and Their Uses

Finding the right saw blade for the job is an important element when it comes to any metalworking project. You want to find a blade that gets things done with precision, efficiency, and little in the way of setbacks.

One of the most important things to consider when choosing a blade is the teeth, as they come in different shapes that have different levels of effectiveness depending on the project. Cold Saw Shop is here to go over a few of the common saw blade teeth shapes and their uses to help you figure out which one can work best for your specific needs.

The Importance of Selecting the Right Saw Blade

There are many different types of saw blades for metalworking. Finding the right blade for your project can make a huge difference in terms of speed, accuracy, and the quality of the cut.

For metalworkers, selecting the appropriate blade isn’t just about matching the tool to the task; it’s about optimizing performance and ensuring safety. Using the wrong blade can lead to poor results, increased wear and tear on equipment, and even safety hazards.

By understanding the different types of saw teeth, you can gain a clearer understanding of which type is best for individual jobs. By doing so, you can enhance your productivity and ensure that every cut is precise and clean. When you know the right blade to use, you can also reduce waste since you’re less likely to damage materials with an unsuitable blade.

Basic Anatomy of Saw Blades

Before exploring the various tooth shapes, it’s crucial to understand the basic anatomy of a saw blade. A typical saw blade consists of several integral parts that each have an important role to play.

Body

The body of the blade usually comprises high-speed steel or carbide, and its sturdiness provides structure and stability.

Set

The set of a blade refers to the specific positioning or bend of the teeth. This feature is essential for creating a kerf, or the slot that the blade cuts into the material.

Gullet

The gullet is the space between each tooth, which allows for chip removal and cooling during cutting.

Tooth Pitch

Finally, tooth pitch is the distance between successive teeth and can vary widely depending on the blade’s intended use.

Flat Top Grind (FTG) Tooth Shape

Flat top grind (FTG) is a common saw blade tooth shape for metalworking projects. This design features teeth that have flat tops, which are ideal for making rip cuts along metal sheets or bars.

The FTG tooth shape excels in rough cutting applications where speed is a larger factor than precision. FTG blades are beneficial when working with thick metals that require deep cuts. The shape offers an aggressive cutting angle that ensures efficient material removal while maintaining a stable cutting process.

Alternate Top Bevel (ATB) Tooth Shape

The alternate top bevel (ATB) tooth shape has teeth that alternate between left and right bevels. The distinct design of this blade makes it easier for metalworkers to create clean cuts with minimal burrs. ATB blades are common on jobs that involve cutting metal sheets or tubs because they require a smooth finish.

Using an ATB blade in metalworking can help enhance productivity and minimize the need for secondary finishing processes. These blades are versatile and can handle a variety of metals, from aluminum to copper.

While they excel in fine cutting tasks, ATB blades may not be the best choice for heavy-duty applications due to their thinner teeth, which are more susceptible to wear over time.

Triple Chip Grind (TCG) Tooth Shape

Another popular blade option is the triple chip grind (TCG), which features a versatile tooth shape that combines the benefits of FTG and ATB designs. TCG blades feature a sequence of alternating teeth—one flat-top tooth followed by a trapezoidal tooth.

One of the key advantages of TCG blades is their ability to withstand wear and maintain sharpness over prolonged use. Their general construction and beneficial traits make them an ideal option for cutting into nonferrous metals, stainless steel, and other tough materials. The combination of tooth shapes reduces vibration during cutting, resulting in a more stable operation and extending the lifespan of the blade.

High-Alternate Top Bevel (Hi-ATB) Tooth Shape

A list of the common saw blade teeth types and their uses wouldn’t be complete without the high-alternate top bevel (Hi-ATB) blades. Metalworkers enjoy these blades because they provide incredibly smooth finishes. Hi-ATB blades offer more pronounced bevel angles than the standard ATB blades and excel in reducing tear-out and delivering superior surface quality.

The sharp edges of Hi-ATB blades allow for precise cuts, making them ideal for thin metals and delicate materials. However, because they feature finer teeth, they generally require more hands-on upkeep and more frequent sharpening to help maintain their performance.

Combination Tooth Shape

Combination blades offer a blend of cutting capabilities by incorporating multiple tooth shapes in a single design. These blades typically feature groups of FTG and ATB teeth, making them highly versatile. Combination blades can perform both rough cuts and fine finishes, which helps them perform in a wider range of metalworking tasks. This flexibility is advantageous for metalworkers who need a single blade to tackle various projects without constantly switching tools.

The unique tooth arrangement of combination blades allows them to handle different thicknesses and types of metals efficiently. While they may not excel in a specific application, their adaptability makes them a valuable addition to any metalworker’s toolkit.

Variable Tooth Shape

Variable tooth blades help reduce vibration and noise during cutting. By altering the spacing and height of the teeth, these blades achieve smoother cuts with less resistance. This feature is beneficial when working with thin metals or delicate materials that are prone to deformation.

For metalworkers concerned about precision and safety, variable tooth blades provide an optimal solution. They deliver clean cuts with minimal burrs while maintaining a stable operation.

To all metalworking professionals and enthusiasts, when it comes to maintaining the peak performance of your equipment, don’t overlook the importance of blade care. At Cold Saw Shops, we understand that the right and properly maintained blade can make all the difference in your projects.

That’s why we not only offer high-quality circular blades tailored to your needs but also provide expert cold saw sharpening services. Our sharpening ensures that your blades remain in top-notch condition, providing precise, clean cuts every time. Contact us today to explore our range of products and services, and let us help you achieve the best results in your metalworking endeavors.