A Complete Guide to Maintaining Your Cold Saw

Metalworking is a labor-intensive field that requires a steady hand and high-quality equipment. Cold saws are a popular option for this craft because of their strength and reliability. However, knowing how to take care of your equipment is vital to prolonging its lifespan to best serve your needs.

Cold Saw Shop is here with a complete guide to maintaining your cold saw to help you get the most out of your gear.

Understanding the Cold Saw’s Anatomy

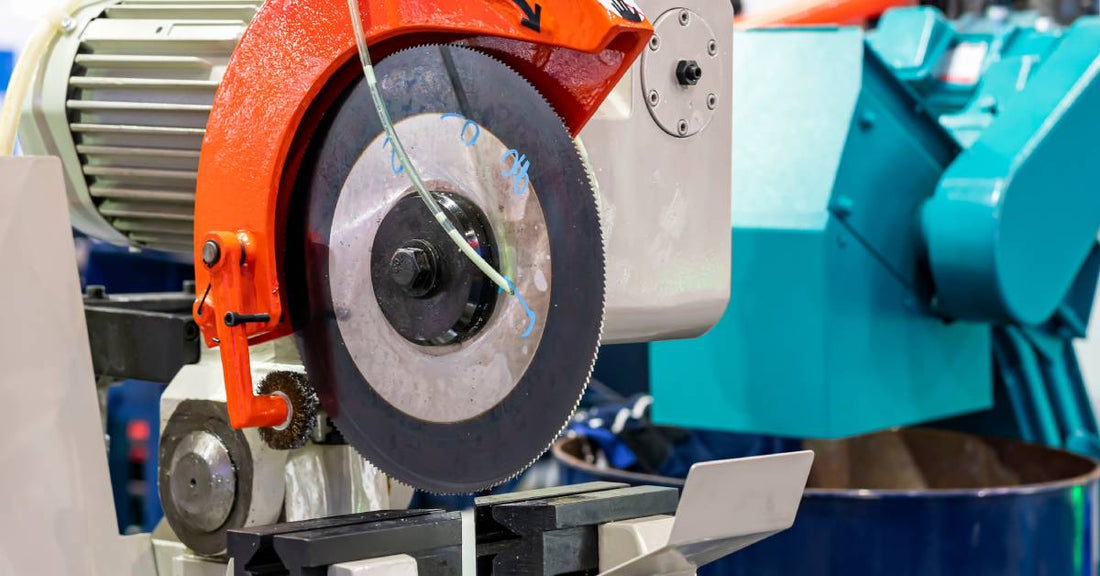

It’s a good idea to understand the inner workings of your saw before you start worrying about maintenance. A cold saw consists of a circular metal blade (usually made of high-speed steel or tungsten carbide-tipped teeth), a motor, and a cooling system, among other components. Each part plays a vital role in achieving clean, burr-free cuts on metal. Knowing these parts will help you identify issues during maintenance.

The motor keeps your saw running, providing the necessary torque to cut through metal. The cooling system, often using lubrication or coolant, prevents overheating, which can lead to blade damage. The blade’s tooth geometry determines the quality of the cut. Familiarizing yourself with these parts will make maintenance more intuitive and effective.

Cleaning Your Cold Saw

Regularly cleaning your cold saw is an important part of maintaining it. Metal shavings, dust, and debris often accumulate in various parts of the saw, which can lead to malfunction or damage. After each use, make it a habit to clean the blade and surrounding areas. Use a brush or compressed air to remove metal particles that can interfere with the saw’s operation.

Don’t forget to clean the cooling system. Over time, debris can contaminate your coolant system, reducing its effectiveness. Drain the old coolant routinely, and replace it with fresh fluid to ensure optimal performance. This step not only maintains your saw’s efficiency but also extends the life of the blade by preventing overheating.

Inspecting the Blade for Wear

The blade is the most critical component of your cold saw, and inspecting it regularly is a big part of maintenance. Blades often dull or experience damage over time, affecting the quality of your cuts. Take the time to look for signs of wear, such as chipped or worn-out teeth, which could indicate the need for sharpening or replacement.

A dull blade compromises cut quality and places extra strain on the motor. A sharp blade ensures smoother cuts and reduces motor workload. Keep a record of your blade’s usage, as this can help predict when you need to perform maintenance or replace the blade. Blades typically show wear after numerous cuts, so frequent inspections maintain performance.

Lubrication and Coolant Maintenance

Proper lubrication is essential for the smooth operation of your cold saw. It reduces friction between moving parts, preventing wear and tear. Regularly check lubrication levels and properly lubricate all mechanical components. Look carefully for signs of dryness or squeaking, and try to fix them as soon as possible to avoid damage.

Coolant maintenance is equally important. A well-maintained cooling system prevents the blade from overheating, which can warp or damage it. Make sure the coolant is at the right level, and replace it if it becomes too dirty. Clean the coolant reservoir, and check for any blockages in the system that might impede flow.

Checking Electrical Components

Electrical components are essential aspects of your cold saw’s functionality. Take the time to check the motor and electrical connections for signs of wear or damage. Loose wires or faulty connections can cause your saw to perform erratically or even pose a safety hazard.

Inspect the power cord and plug for any frays or exposed wires. Replace damaged cords immediately to prevent electrical failures. A simple but often overlooked step is checking that the on/off switch is functioning correctly. A malfunctioning switch can lead to unexpected startups or shutdowns, which can be dangerous.

Aligning Saw Components

Precision is crucial in metalworking, and properly aligning your cold saw’s components ensures high-quality cuts. Misalignment can lead to inaccuracies and unnecessary blade wear. Regularly check that the blade, vise, and material feed align correctly. Also, ensure that the blade is perpendicular to the work surface. Use a square tool to verify alignment. Misalignment here may result in angled cuts that are unacceptable for most metalworking projects.

Replacing Worn Parts

Even with regular maintenance, parts of your cold saw will eventually wear out and need replacement. Keeping an eye on the condition of these components is crucial for ongoing performance and safety. The blade, motor brushes, and drive belts are items you should keep an eye on.

When replacing the blade, ensure you select the correct type and size of saw blade for steel cutting. Mismatched blades lead to poor performance and can damage the saw. When in doubt, consult your saw’s manual or manufacturer for guidance on selecting the right blade.

Safety Measures in Maintenance

When working with saws in any capacity, you must keep safety in mind. Always disconnect the power before performing any maintenance tasks. This simple step prevents accidental startups that could lead to injury.

Wear appropriate personal protective equipment (PPE), such as gloves and safety glasses, when working on your saw. Wearing the right gear protects you from sharp blades and flying debris. Use the right tools for maintenance tasks to avoid damaging components or injuring yourself.

Keeping a Maintenance Schedule

Creating and adhering to a maintenance schedule is an effective way to ensure your cold saw remains in optimal condition. Regularly scheduled maintenance tasks, such as cleaning, lubricating, and inspecting components, prevent issues from developing into significant problems.

We recommend keeping a notepad in your workshop and documenting each maintenance session, noting any adjustments, replacements, or other factors by date. This record can help identify patterns and inform future maintenance needs. A proactive approach to maintenance will extend your saw’s lifespan and enhance its performance.

Hopefully, this complete guide to maintaining your cold saw will help you enhance your metalworking projects. When you need replacement blades for your saw, Cold Saw Shop is here to help. We have a wide range of blades in many different shapes, sizes, and styles to meet your needs. Learn more about our equipment by browsing our online catalog or contacting us anytime with any questions, comments, or concerns.