7 Common Errors People Make Using Cold Saws

You have invested in a powerful tool. A cold saw can consistently produce precise, clean cuts through metal. Yet, you find yourself dealing with burred edges, slow cuts, and blades that wear out far too quickly.

These complications are all signs that you need to correct something in the cutting process. To prevent failed projects, avoid these common errors when using cold saws.

Low-Quality Tools

The foundation of any successful metalworking project is the quality of the tools you use. You might think you are saving money by choosing cheap, low-quality blades, but this is a common misconception that costs you more in the long run.

A substandard blade will dull quickly, produce rough cuts, and may even damage your cold saw machine. Using a poor-quality blade puts unnecessary strain on your saw’s motor, leading to premature wear and expensive repairs.

To ensure you get the clean, burr-free cuts you expect, you must start with a superior blade. At Cold Saw Shop, we provide high-speed steel (HSS) blades engineered to be durable and precise, so these blades are reliable for a wide range of projects.

Incorrectly Matching Equipment Requirements

Different cold saw machines have specific requirements for blade size, thickness, and arbor hole dimensions. Using a blade that does not match your saw’s specifications can lead to vibration, which compromises cut quality and creates a safety hazard.

Furthermore, the material you are cutting dictates the type of blade you should use. A blade designed for mild steel may not perform well when cutting stainless steel or aluminum, as each metal has unique properties that require a specific tooth count and geometry.

Do you know if your blade is truly the right match for your machine and material? Taking the time to verify these requirements ensures your equipment works in harmony, delivering the efficiency and precision you need.

Not Breaking In the Blade

A new blade has razor-sharp teeth that are initially brittle. Putting it under full load right away can cause microscopic fractures in the cutting edges.

To prevent premature dulling and chipping, break in a new blade by running it at about half the normal feed rate and speed for the first several cuts. A gentle introduction allows the cutting edges to hone themselves, strengthening the teeth and preparing them for the demands of full-scale production.

Improper Cutting Technique

The two most important variables to control are the speed and the feed rate. Running the blade too fast can generate excessive heat, which can warp the blade and the material you are cutting. An aggressive feed rate can overload the blade’s teeth. This can result in the teeth chipping or breaking.

Conversely, an excessively slow feed rate creates unnecessary friction and heat. The teeth will rub against the material instead of cutting it, thereby turning the blade dull.

Finding the right balance for your specific material is essential. You must pay attention to the saw’s specifications and observe the chips it produces. Fine, powdery dust indicates that your speed is too high or the feed is too low, while large, blue-tinted chips suggest the opposite. Mastering an expert-level cutting technique will protect the blade and allow you to produce smooth, precise finishes every time.

Overlooking Safety Steps

Even with the best technique, you must never neglect fundamental safety protocols. A cold saw is a powerful piece of machinery that demands respect and caution to prevent serious injury.

While the saw is in operation, you must remain vigilant. Clamp the workpiece securely before you begin a cut. Otherwise, the blade could violently throw a loose piece of metal.

Keep your hands and arms clear of the blade’s path at all times and never try to adjust the workpiece or clear away chips while the saw is running.

After you complete a cut, wait for the blade to come to a complete stop before you retrieve your material. These steps might seem basic, but consistently following them is what separates a safe workshop from a dangerous one.

Skipping Sharpening Service

Even if you can avoid accidents, you cannot avoid the eventual dulling of your blade. Many operators make the mistake of using a blade long after it has lost its sharp edge, which leads to poor cut quality and puts immense strain on the saw.

A dull blade requires more force to cut, generating excess heat and increasing the likelihood of chipping teeth or damaging your saw’s motor.

When you feel your saw struggling to cut, it is time to seek out a professional cold saw blade sharpening service. At Cold Saw Shop, we use precision equipment to expertly sharpen your blades, extending their life and saving you money.

Forgetting To Clean the Cold Saw

After you have finished your work, the final step is to clean it. One of the common errors people make using cold saws is to go right onto the next project, but this is a big mistake.

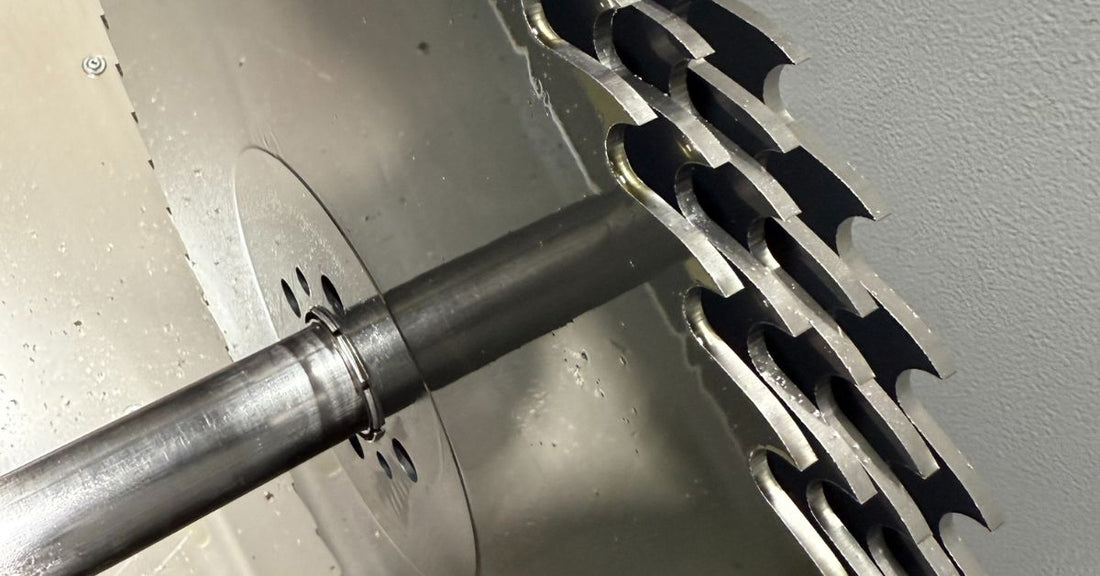

Metal chips and cutting fluid can build up on your saw blade and within the machine itself. This buildup can interfere with the blade’s performance, causing it to bind or cut inaccurately. Over time, the accumulated debris can lead to corrosion and damage to the saw’s components.

You should make it a habit to thoroughly clean the blade and saw after each use. A simple wire brush can remove chips from the blade’s gullets, and a quick wipe-down of the machine will prevent long-term issues. This simple act of maintenance will keep the equipment in top condition and always prepared for the next job.

Sharpen Up and Successfully Use a Cold Saw

Avoiding these common mistakes will transform your metal cutting operations, leading to exceptional results, long-lasting tools, and a safe workshop.

Equip yourself with the best tools for the job by getting your high-performance blades from Cold Saw Shop. And when your blades eventually need a refresh, trust our expert cold saw blade sharpening service to restore their cutting power.