4 Tips To Help You Determine if You Need a Cold Saw

When it comes to metal cutting, the tools you use can significantly impact the quality of your work. Among these tools, saw blades play a pivotal role. Deciding whether to buy this tool can be a major decision for your business, so it's important to choose wisely. Below, we've outlined four expert tips to help you determine if you need a cold saw.

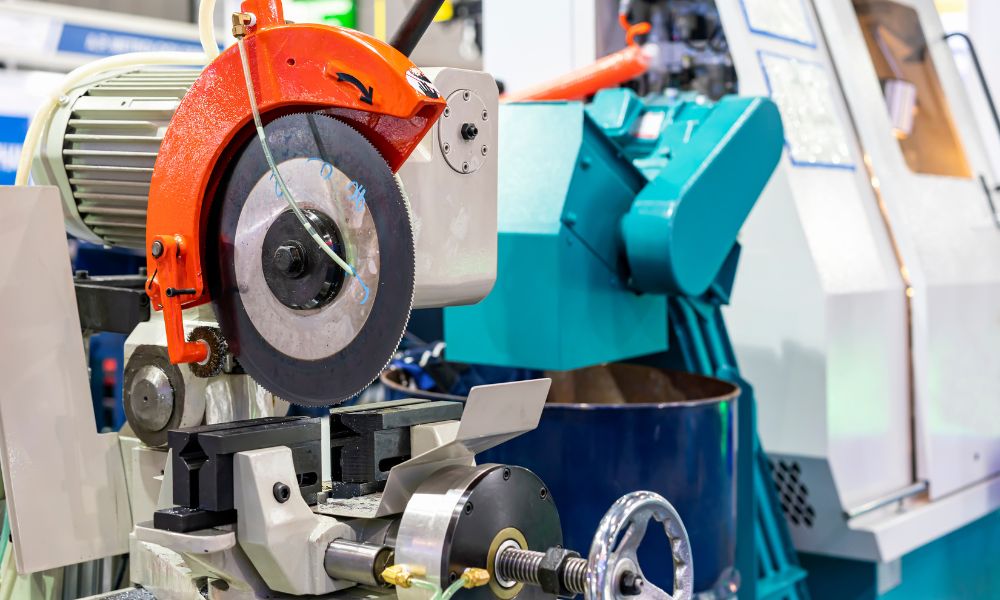

Understand the Types of Saw Blades

Each blade type has unique features and is ideal for a particular purpose. Some common types include circular, band, jigsaw, and reciprocating saw blades. Knowing the differences between these options is crucial to determine which one will work best for your project.

Often, circular saws are best for making straight cuts in metal, though they can cut other materials such as wood. Moreover, this blade type comes in various sizes, allowing for versatility in tooth count. The most popular types of circular blades are carbide-tipped and high-speed steel blades.

Review the Type of Material You Cut

The next tip to determine if you need a cold saw is to think about the type of material you frequently cut. Is it predominantly metal or wood? Cold saws are best at making clean and precise cuts in many metal types, such as steel, stainless steel, and aluminum.

Unlike abrasive cut-off saws that generate heat and can cause the metal to warp, a cold saw keeps the cutting surface cool as long as you use the required lubricants. Always review the product description to make sure you’re using the required lubricant.

Evaluate the Size of Your Projects

You should also consider the size of your projects, as many professionals in the metal fabrication field find cold saws essential. They are particularly useful for ferrous and nonferrous metal pieces in a range of sizes.

Typically, professionals use cold saws for projects such as cutting pipes, tubes, and beams. These blades are ideal for professionals working in the fields of welding, metal fabrication, engineering, and other industries that require metal cuts.

Consider the Style of Cuts You Need

Carefully consider the style of cuts you need: straight, angled, or mitered. Cold saws are ideal for straight and angled cuts because of their precise nature. The design of a cold cut saw blade allows for precise angle adjustments, enabling you to make the most accurate cuts in the material you work with.

Shop for High-Grade Saws

The right tools can make all the difference, and using superior saw blades is crucial for achieving professional results. When shopping for a cold saw, choose a reputable brand known for high-quality blades.

Cold Saw Shop sells circular saw blades in various sizes with different teeth counts. We also have blades specifically designed for cutting different materials, such as aluminum or stainless steel. Invest in the best saw blades to ensure top-notch productivity and excellent results.